Top 5 Benefits of Using Round Carbide Rods in Manufacturing and Tooling Applications

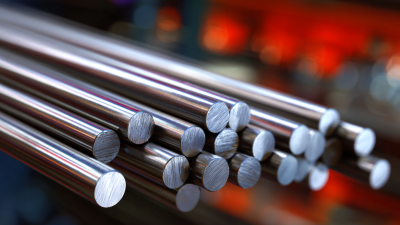

In the fast-paced world of manufacturing and tooling applications, the choice of materials is crucial for ensuring efficiency, precision, and longevity. Among the vast array of options available, Round Carbide Rods stand out due to their exceptional properties and versatility. These rods are increasingly becoming the go-to solution for manufacturers seeking to enhance their operations and improve product quality.

In this article, we will explore the top five benefits of using Round Carbide Rods, illustrating why they are an indispensable component in today's advanced manufacturing landscape.

One of the primary advantages of Round Carbide Rods is their unparalleled hardness and wear resistance, making them ideal for cutting tools and machining operations. This unique characteristic not only increases tool life but also reduces the frequency of replacements, ultimately leading to significant cost savings.

Furthermore, Round Carbide Rods offer enhanced thermal stability, allowing them to maintain performance even under extreme conditions. As we delve into the specific benefits, it will become evident how these rods can revolutionize manufacturing processes and contribute to a more streamlined and effective production environment.

Maximizing Precision: The Role of Round Carbide Rods in Tool Fabrication

Round carbide rods play a crucial role in maximizing precision within tool fabrication. Their high density and exceptional hardness make them ideal for producing tools that require sharp edges and durability. The fine grain structure of carbide enhances wear resistance, enabling manufacturers to create tooling that maintains accuracy over extended periods of use. This reliability is vital in sectors that demand meticulous performance, such as aerospace and automotive industries.

When utilizing round carbide rods, it’s essential to adopt best practices for machining. **Tip 1**: Ensure proper coolant usage during machining processes to reduce heat, which can affect the integrity of the carbide. **Tip 2**: Opt for the right cutting tools designed specifically for carbide materials to maximize efficiency and minimize wear on the equipment. Incorporating these tips not only enhances the lifespan of tools but also significantly improves the overall quality of the fabrication process.

Furthermore, round carbide rods contribute to streamlining production workflows. With their ability to be easily ground and shaped, manufacturers can efficiently create custom tools tailored to specific applications. **Tip 3**: Regularly monitor tool wear and re-sharpen or replace as necessary to maintain optimal performance and precision over time. This proactive approach ensures that the tools continue to meet demanding production standards while extending their service life.

Top 5 Benefits of Using Round Carbide Rods in Manufacturing and Tooling Applications

| Benefit |

Description |

Application |

Material Properties |

| Higher Durability |

Resistant to wear and deformation under high pressure. |

Cutting tools for metal working. |

High hardness and toughness. |

| Improved Machining Precision |

Ensures high precision in manufacturing processes. |

Milling and turning operations. |

Stable size and shape retention. |

| Versatility |

Can be used in various applications across different industries. |

Automotive, aerospace, and manufacturing tools. |

Compatible with many materials including steel and aluminum. |

| Cost-effective |

Reduces downtime and replacement costs due to prolonged lifespan. |

Production lines requiring high throughput. |

High abrasion resistance. |

| Enhanced Surface Finish |

Produces smoother surfaces on machined parts. |

Finishing processes in mold making. |

Fine-grained microstructure. |

Enhancing Durability: Why Carbide Rods Outperform Other Materials

Carbide rods are increasingly becoming the material of choice in manufacturing and tooling applications due to their exceptional durability. Unlike traditional materials, carbide rods boast a hardness that allows them to withstand extreme wear and tear, making them ideal for cutting tools and heavy machinery. This superior endurance not only enhances the longevity of the tools made from carbide but also results in lower production costs over time, as fewer replacements are required.

However, to maximize the benefits of using carbide rods, it's essential to consider proper techniques during machining and tooling processes. For instance, it is advisable to select appropriate speed and feed rates when working with carbide to avoid excessive heat buildup, which could affect the integrity of the tool. Additionally, implementing regular maintenance practices can further extend the life of carbide tools, ensuring they perform at optimal levels.

Another crucial tip is to choose the right carbide grade for specific applications. Different grades of carbide offer varying degrees of toughness and wear resistance, so aligning the material properties with the demands of the job can result in improved efficiency and output quality. By focusing on these factors, manufacturers can harness the outstanding characteristics of carbide rods for superior performance.

Cost Efficiency: Long-Term Savings with Round Carbide Tools

Cost efficiency is a crucial aspect for businesses in manufacturing and tooling applications, and round carbide rods play a significant role in achieving long-term savings. These rods, known for their exceptional hardness and wear-resistance, enable manufacturers to produce tools that maintain their cutting performance over extended periods. By using round carbide tools, companies reduce the frequency of replacements and repairs, leading to significant cost savings over time.

Moreover, the durability of round carbide rods translates to less downtime in production. When tools last longer and require fewer replacements, manufacturers can optimize their operations and allocate resources more effectively. This efficiency not only lowers operational costs but also enhances productivity, allowing businesses to focus on growth and innovation. As companies increasingly strive to maximize their budgets, the long-term investment in round carbide tools becomes evident, reinforcing their popularity in the tooling industry.

Cost Efficiency: Long-Term Savings with Round Carbide Tools

Versatility in Application: Where Round Carbide Rods Shine in Manufacturing

Round carbide rods are an essential element in various manufacturing and tooling applications due to their exceptional versatility. Their hardness and wear resistance allow for exceptional performance across a wide range of tools, from cutting edges to wear components. Industries such as aerospace, automotive, and manufacturing utilize these rods to create precision instruments that must withstand extreme conditions. The ability to maintain sharp edges and resist chipping makes round carbide rods a preferred choice for demanding applications.

When selecting round carbide rods, consider the specific requirements of your project. Tips for optimizing their use include understanding the right diameter for your tooling needs and ensuring the rod is ground to the proper tolerance for your application. Additionally, regular maintenance and inspection can prolong the life of tools made from carbide, ultimately leading to increased efficiency and reduced downtime in manufacturing processes.

Another critical aspect is the selection of the right carbide grade. Different grades offer varying degrees of toughness and hardness, making it essential to match the material properties with the intended use. By making informed choices based on application demands, manufacturers can significantly enhance productivity and product quality.

Streamlining Production: How Carbide Rods Improve Operational Efficiency

The use of round carbide rods in manufacturing and tooling applications is becoming increasingly popular, primarily due to their ability to streamline production processes and enhance operational efficiency. These rods, known for their durability and precision, can significantly reduce downtime associated with tool changes and maintenance. By integrating carbide rods into manufacturing workflows, businesses can achieve a smoother production line, which, in turn, accelerates output and improves product quality.

Tips for maximizing the benefits of carbide rods include regular maintenance to ensure optimal performance and investing in high-quality cutting tools. Utilizing these rods can also lead to lower replacement costs over time, as their robustness reduces the need for frequent tool replacements. Additionally, businesses should consider training their staff on the best practices for handling and using carbide tools to further enhance efficiency.

As industries adapt to evolving market demands and strive to improve their manufacturing processes, the adoption of advanced materials like round carbide rods will continue to play a crucial role in achieving operational excellence. By embracing these innovative solutions, manufacturers can stay competitive while also meeting the needs of their clients more effectively.

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us