Top 10 Benefits of Using Tungsten Carbide Plates in Industrial Applications

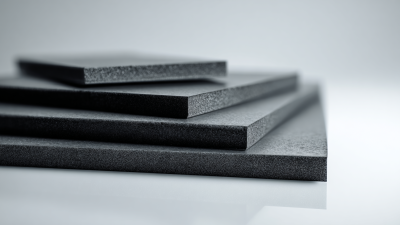

In the ever-evolving landscape of industrial applications, the use of Tungsten Carbide Plates has emerged as a pivotal advancement that enhances efficiency and durability. Dr. Emily Carter, a leading expert in material science, emphasizes this innovation, stating, "The superior hardness and wear resistance of Tungsten Carbide Plates make them an ideal choice for demanding industrial environments." This assertion underscores the transformative impact that these plates can have on various sectors, from manufacturing to construction.

Tungsten Carbide Plates are not only designed to withstand extreme conditions but also to reduce downtime and maintenance costs in industrial operations. As industries continually seek ways to optimize their processes and improve product longevity, the benefits of incorporating Tungsten Carbide Plates are becoming increasingly apparent. This article delves into the top 10 benefits of using Tungsten Carbide Plates, exploring how they can revolutionize industrial applications and contribute to sustainable growth. By understanding these advantages, businesses can better equip themselves to tackle the challenges of modern manufacturing and maintain a competitive edge in their respective markets.

Benefits of Extreme Durability of Tungsten Carbide Plates

Tungsten carbide plates are renowned for their extreme durability, making them an invaluable asset in various industrial applications. These plates possess exceptional hardness, allowing them to withstand the harshest conditions without significantly wearing down. Unlike softer materials, tungsten carbide is resistant to scratches, dents, and other types of damage, ensuring that machinery and equipment maintain higher efficiency and longevity. This durability translates to reduced maintenance costs and less frequent replacements, making tungsten carbide plates a cost-effective solution in the long run.

When utilizing tungsten carbide plates, it's important to consider the environment in which they will be applied. For instance, while they excel in high-impact and high-temperature situations, their performance can further be enhanced by ensuring proper alignment and support during installation. This helps distribute the load evenly across the plate, minimizing the risk of breakage. Regular inspections are also beneficial; monitoring for signs of wear can prevent unexpected downtime in industrial operations.

In addition to their strength, tungsten carbide plates offer versatility in design and application. Industries ranging from mining to manufacturing can find customized solutions that meet specific operational needs. When selecting tungsten carbide plates, prioritize sourcing from reputable suppliers to ensure you receive quality material that meets the necessary industrial standards, thereby maximizing performance and durability in your applications.

Top 10 Benefits of Using Tungsten Carbide Plates in Industrial Applications

| Benefit |

Description |

Application Areas |

| Extreme Hardness |

Tungsten carbide plates provide superior hardness, making them highly resistant to wear and abrasion. |

Mining, construction, manufacturing |

| Enhanced Durability |

These plates can withstand extreme conditions, extending the life of tools and equipment. |

Heavy machinery, cutting tools |

| Corrosion Resistance |

Tungsten carbide is resistant to corrosion from chemicals and moisture. |

Oil and gas, chemical processing |

| High Density |

The high density of tungsten carbide plates provides stability and strength under heavy loads. |

Aerospace, automotive |

| Versatility |

Can be custom-designed for various applications, making them adaptable to different industries. |

Manufacturing, tool making |

| Cost-effective |

Longevity reduces the need for frequent replacements, leading to cost savings over time. |

Industrial manufacturing, construction |

| Excellent Wear Resistance |

Significantly reduces wear during machining operations, prolonging tool life. |

Metalworking, machining |

| Thermal Stability |

Maintains integrity and performance in high-temperature environments. |

Aerospace, steel industries |

| Environmental Resistance |

Performs well in harsh environments, making it suitable for various industrial settings. |

Construction, mining, recycling |

| Improved Precision |

Facilitates high-precision cutting and machining operations. |

Manufacturing, fabrication |

Applications in Heavy Machinery and Equipment Protection

Tungsten carbide plates are increasingly becoming a preferred choice in heavy machinery and equipment protection due to their exceptional hardness and wear resistance. These plates exhibit a hardness of 8.5 to 9 on the Mohs scale, making them nearly four times harder than steel. According to a report by the International Journal of Engineering Research and Applications, the use of tungsten carbide in industrial applications can lead to a reduction in maintenance costs by up to 50%, thereby enhancing the efficiency of machinery and extending its operational lifespan. This is particularly vital in sectors such as mining, construction, and manufacturing, where equipment is subjected to extreme conditions and abrasion.

Moreover, the versatility of tungsten carbide allows it to be tailored for various applications within heavy machinery. For instance, it is commonly utilized in the production of wear parts, cutting tools, and as protective linings for bins and chutes. The American Society of Mechanical Engineers highlights that integrating tungsten carbide plates can improve operational reliability by providing better resistance against impact and abrasion. This is critical in preventing unexpected downtimes, which can result in significant financial losses for businesses. By incorporating tungsten carbide plates, industries not only enhance the durability of their equipment but also contribute to overall productivity and safety in their operations.

Top 10 Benefits of Using Tungsten Carbide Plates in Industrial Applications

Resistance to Wear and Tear in Harsh Environments

Tungsten carbide plates are increasingly being utilized in various industrial applications due to their exceptional resistance to wear and tear, particularly in harsh environments. The unique properties of tungsten carbide allow it to withstand extreme abrasive conditions, making it an ideal choice for industries such as mining, construction, and metalworking. With a hardness rating that is significantly higher than that of traditional materials, tungsten carbide plates provide an unparalleled level of durability, reducing the need for frequent replacements and minimizing downtime in production processes.

In harsh environments where machinery and tools face constant exposure to abrasive materials, the longevity of tungsten carbide plates becomes a crucial factor. These plates not only resist wear but also maintain their structural integrity under high pressure and temperature conditions. This resistance to degradation ensures that operators can rely on their equipment for extended periods, thereby enhancing overall productivity and efficiency. The ability to perform reliably in such challenging situations underscores the practical value of tungsten carbide plates in safeguarding investments and ensuring optimal operational performance across a range of demanding industrial applications.

Cost-Effectiveness of Tungsten Carbide in Long-Term Use

Tungsten carbide plates have become a vital component in various industrial applications, primarily due to their remarkable cost-effectiveness over time. According to a recent industry report by the National Institute of Standards and Technology (NIST), tungsten carbide exhibits up to five times the wear resistance of steel, making it a preferred material for tools and machinery subjected to extreme conditions. This durability results in reduced replacement costs and lower recalibration expenses, ultimately leading to significant savings for businesses in the long run.

Investing in tungsten carbide plates not only minimizes downtime for equipment replacement but also enhances productivity. A survey conducted by the American Society of Mechanical Engineers (ASME) revealed that companies using tungsten carbide tools reported an average increase in operational efficiency by 30%. This improvement can largely be attributed to the consistent performance and lower maintenance needs associated with tungsten carbide products, which translates to fewer disruptions in production schedules.

Tips: When considering tungsten carbide for industrial use, carefully assess the specific demands of your application to maximize these cost benefits. Moreover, regular maintenance and inspections can extend the lifespan of tungsten carbide components even further, ensuring you get the most value from your investment. By strategically utilizing this durable material, companies can not only cut expenses but also achieve greater overall efficiency in their operations.

Versatility in Manufacturing and Industrial Processes

Tungsten carbide plates have emerged as a game-changer in manufacturing and industrial processes due to their exceptional versatility and performance. With a hardness that's second only to diamond, tungsten carbide offers unparalleled resistance to wear and abrasion. According to a report from the International Journal of Advanced Manufacturing Technology, the use of carbide tools can extend tool life by up to 50%, significantly reducing production downtime and costs. This durability makes tungsten carbide ideal for a range of applications, from machining high-strength materials to manufacturing components that withstand extreme temperatures and pressures.

In addition to their mechanical properties, tungsten carbide plates contribute to the efficiency of various industrial processes. Their ability to be precisely machined allows for the creation of custom geometries and complex designs that meet the specific needs of different sectors, including aerospace and automotive. A study by the American Society of Mechanical Engineers noted that components made from tungsten carbide could improve operational efficiency by up to 30% when compared to traditional materials. The versatility of these plates ensures they can be utilized across various settings, enabling manufacturers to optimize their operations while maintaining the high quality and reliability of their products.

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us