10 Best Round Carbide Blades for Precision Cutting in 2023

In the realm of precision cutting, the importance of using high-quality tools cannot be overstated. Among these tools, the Round Carbide Blade stands out for its exceptional durability and cutting precision. According to a recent report from the International Tool Industry Association, the demand for carbide blades is projected to grow by 8% annually, driven by advancements in manufacturing technologies and the increasing need for accurate cutting solutions in various industries. This trend underscores the significance of selecting the right blade, not only for efficiency but also for achieving optimal results.

Expert in cutting tool technologies, Dr. Emily Cartwright, emphasizes the pivotal role of Round Carbide Blades in modern machining processes, stating, "The evolution of carbide blade design has revolutionized precision cutting, allowing for finer operations and reduced waste." Her insights further highlight how the selection of appropriate blades can significantly impact production quality and operational costs. As we explore the ten best Round Carbide Blades for precision cutting in 2023, it is crucial to consider these insights and the broader market trends shaping the industry today.

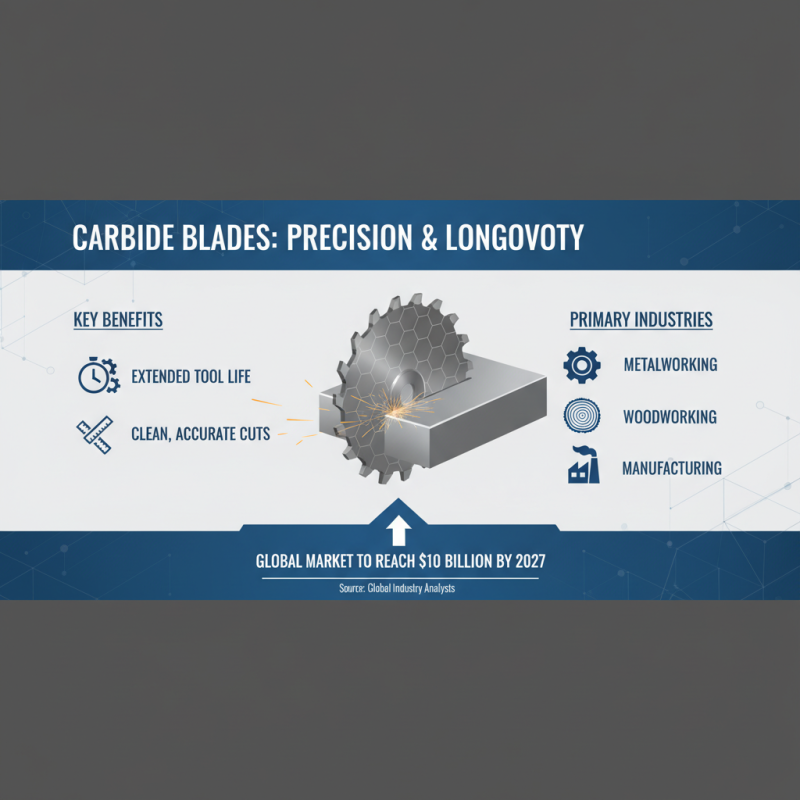

Overview of Carbide Blades and Their Applications in Precision Cutting

Carbide blades are essential tools in various industries due to their longevity and precision cutting capabilities. These blades are typically made from tungsten carbide, known for its hardness and resistance to wear. In precision cutting applications, such as metalworking, woodworking, and manufacturing, carbide blades deliver clean cuts with minimal chipping or damage to the material. According to a report by the Global Industry Analysts, the carbide tool market is projected to reach USD 10 billion by 2027, emphasizing the growing demand for high-performance cutting tools across sectors.

The versatility of carbide blades allows them to be utilized in diverse applications. In woodworking, for instance, they are used in table saws and circular saws for making intricate cuts, while in metalworking, their high cutting speeds significantly improve productivity and efficiency. The report from Fortune Business Insights highlights that precision cutting tools with carbide coating can reduce production costs by up to 30%, making them an attractive option for manufacturers looking to enhance their operational efficiency. Furthermore, advancements in carbide technology have led to the development of blades that maintain cutting performance at high temperatures, critical for demanding industrial applications.

Key Features and Specifications of High-Quality Round Carbide Blades

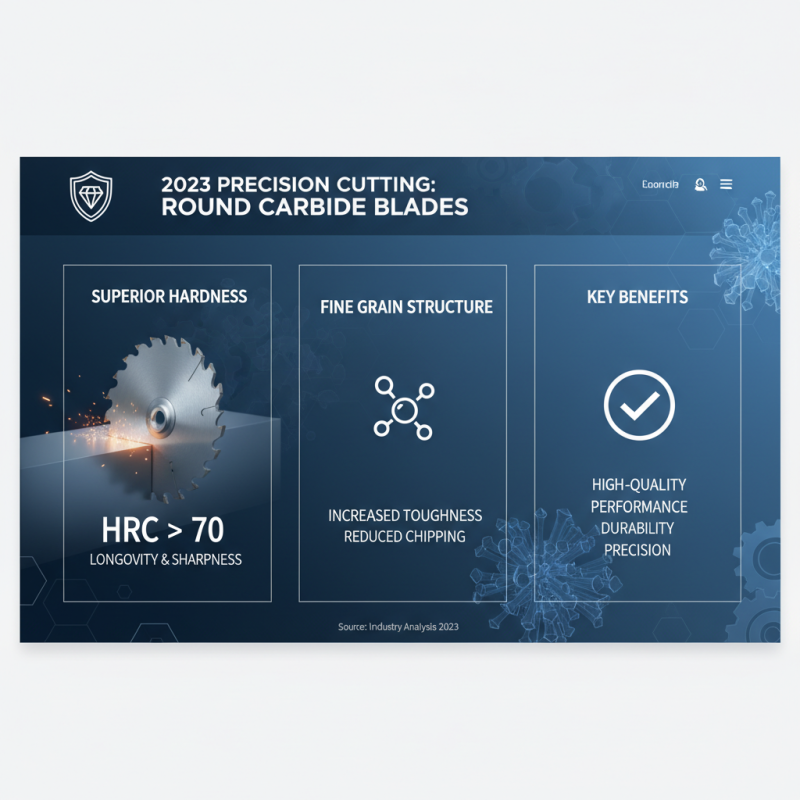

When selecting round carbide blades for precision cutting in 2023, it's essential to focus on key features and specifications that ensure high-quality performance. The best blades exhibit superior hardness, typically measured on the Rockwell scale, which often exceeds HRC 70. This hardness directly contributes to the blade's longevity and its ability to maintain sharpness during prolonged use. Furthermore, a fine grain structure in carbide blades enhances their toughness, reducing the likelihood of chipping or breaking, especially under high-stress conditions.

In addition to hardness, the geometry of the blades plays a crucial role in cutting efficiency. A higher tooth count can lead to smoother finishes, making them ideal for applications requiring precision. Industry reports indicate that blades with optimized kerf widths improve cutting speed and reduce material wastage, thus increasing overall productivity. Additionally, blades designed with specific coatings, such as titanium or cobalt, can significantly enhance their wear resistance and reduce friction, making them suitable for high-speed operations.

**Tips**: When choosing a round carbide blade, consider the material you will be cutting. For harder materials, opt for blades with a larger diametric thickness for better performance. Always ensure that the blade specifications align with your machine's capabilities to maximize efficiency and achieve the best results. Regular maintenance, including proper cleaning and storage, can also extend the life of your carbide blades.

Top 10 Round Carbide Blades for Precision Cutting in 2023: A Comprehensive Review

When it comes to precision cutting, the choice of the right

round carbide blade can make all the difference in achieving clean and accurate results. In 2023,

the market offers a variety of high-quality options designed for different applications. This comprehensive review focuses on the

top ten round carbide blades that have been praised for their exceptional performance, durability, and precision. Each blade is

evaluated based on its cutting capacity, material compatibility, and user feedback, ensuring that you can make an informed choice

tailored to your specific needs.

Tips for selecting the best round carbide blades include considering the material you will be cutting. For tougher materials,

opting for blades with higher tooth counts can provide a smoother finish, while those

with fewer teeth are better suited for faster cuts in softer materials. Additionally, always ensure that the blade size matches

your tool to avoid any compatibility issues that may lead to subpar performance or safety hazards.

Another key point is maintenance. Regularly inspecting your blades for

wear and tear can prolong their lifespan. Keeping the blades clean and free from resin buildup will ensure consistent cutting

performance. By following these tips and exploring the ten top-rated blades, you’ll be well-equipped to enhance your precision

cutting projects in 2023.

Comparison of Cutting Performance: Blade Material, Thickness, and Design

When it comes to precision cutting, the material, thickness, and design of round carbide blades play critical roles in performance. According to a report by the International Journal of Advanced Manufacturing Technology, carbide blades are known for their exceptional hardness and wear resistance, making them a preferable choice for cutting through tough materials. This is largely due to the tungsten carbide composition, which provides a cutting edge that lasts significantly longer compared to traditional steel. The statistics indicate that blades made from high-grade carbide can maintain their sharpness up to five times longer, which substantially reduces downtime and increases productivity in industrial applications.

Thickness is another vital factor influencing cutting performance. Research published in the Journal of Manufacturing Processes highlights that a thinner blade typically results in a finer cut and reduced friction, allowing for smoother operations. Optimal thickness ranges can vary depending on the type of material being cut; for example, blades designed for intricate cuts in wood or plastic are generally thinner, around 0.4 to 0.6 mm, whereas those used for tougher metals might be thicker, around 1.0 mm or more. Additionally, the design of the blade—such as the number of teeth and tooth geometry—affects not only the quality of the cut but also the cutting speed.

Blades with optimized tooth designs can achieve impressive feed rates without compromising edge stability, according to data from the Cutting Tool Engineering Journal. This balance between thickness and design is essential for achieving the highest efficiency and precision in cutting tasks.

Future Trends in Carbide Blade Technology and Precision Cutting Techniques

The evolution of carbide blade technology significantly influences precision cutting techniques across various industries. As manufacturers increasingly seek high-performance cutting tools, advancements in carbide formulations have led to blades that are not only more durable but also capable of maintaining sharpness for extended periods. A report from the Global Industrial Tools Market indicates that the demand for carbide cutting tools is expected to grow at a CAGR of 5.2% between 2023 and 2028, highlighting a shift towards high-precision applications in sectors such as woodworking, metalworking, and aerospace.

Furthermore, the future of precision cutting techniques is expected to embrace automation and smart technology integration. Industry analysts from the Precision Cutting Tools Association forecast that by 2025, over 70% of industrial cutting operations will incorporate CNC and automated systems powered by AI to enhance precision and efficiency. This move towards automated systems will not only streamline production processes but also reduce human error, leading to more consistent quality outcomes. The marriage of advanced carbide blade technology with these emerging techniques promises to redefine the standards of precision cutting in the coming years.

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us