How to Choose the Right Milling Cutter for Your Projects?

Choosing the right milling cutter can significantly impact your project's success. Milling cutters come in various shapes and sizes, each designed for specific tasks. Understanding the differences is crucial.

When selecting a milling cutter, consider the material you are working with. Whether it’s wood, metal, or plastic, each material demands a specific type of cutter. The cutter’s geometry is also vital. Different cutting angles affect performance and finish. Additionally, the choice of coating influences durability and efficiency in cutting.

However, many overlook finer details. For example, the cutter's diameter can restrict access in tight spaces. Sometimes, it feels overwhelming to decide. Reflecting on past experiences can help refine your choices. Pay attention to cutting speeds and feeds as they vary. Making the wrong choice may lead to poor results or damage. Ultimately, knowing your project's requirements is key to finding the right milling cutter.

Understanding the Basics of Milling Cutters

Choosing the right milling cutter can significantly impact your project's success. A milling cutter is essential for shaping materials accurately. It comes in various types and sizes, each suited for specific tasks. Understanding these basics is important for achieving desired results.

Different milling cutters have specific uses. For instance, flat end mills create smooth surfaces, while ball end mills can produce curved edges. It’s crucial to match the cutter with the material you are working with. Hard materials require stronger cutters, while softer materials may not need such durability. Not every cutter works well with every material. Experimentation is key. Sometimes, the chosen cutter may chip or wear out quickly.

Using the wrong cutter can lead to issues. You might find that the finish is rough or dimensions are off. This can cost you time and resources. Regularly assessing your choices helps refine your technique. Maintaining your tools is just as vital. A dull cutter can ruin a project, so consider sharpening or replacing it periodically. Reflection on your cutting choices means learning from mistakes and improving your process.

How to Choose the Right Milling Cutter for Your Projects? - Understanding the Basics of Milling Cutters

| Cutting Type |

Material |

Diameter (mm) |

Teeth Count |

Ideal Use Case |

| End Mill |

High-Speed Steel |

12 |

4 |

General-purpose milling |

| Face Mill |

Carbide |

20 |

6 |

Surface finishing |

| Ball Nose Mill |

Cobalt |

10 |

2 |

3D contouring |

| Slab Mill |

HSS |

25 |

10 |

Heavy stock removal |

| Reamer |

Carbide |

8 |

3 |

Precision hole enlarging |

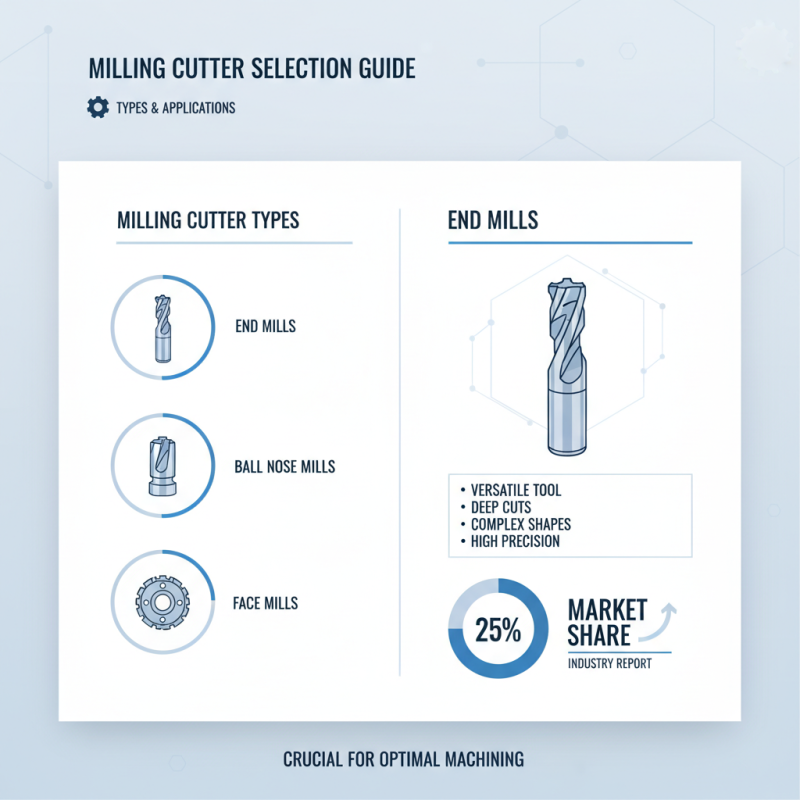

Types of Milling Cutters and Their Applications

When selecting a milling cutter, understanding the different types and their applications is crucial. There are various milling cutters, each designed for specific tasks. For instance, end mills are versatile tools used for making deep cuts and complex shapes. According to recent industry reports, end mills account for approximately 25% of the milling tools market. They excel in operations requiring high precision.

Face mills are another common type. They are primarily used for large surface areas and are ideal for finishing operations. These tools can cover a significant area quickly. Reports suggest that face mills represent around 30% of milling cutter usage in factories. Their ability to provide a smooth finish is vital in industries where precision matters.

In contrast, slab mills and fly cutters serve more specialized functions. Slab mills are preferred for their efficiency in removing bulk material, while fly cutters offer greater flexibility in cut angles. However, they may lead to uneven surface finishes if not used correctly. Each cutter comes with its own set of advantages and limitations. Understanding these nuances helps in making informed choices, ultimately affecting project outcomes.

Factors to Consider When Choosing a Milling Cutter

Choosing the right milling cutter can seem daunting. Several factors can affect your project outcomes. Understanding these factors is essential for making informed decisions.

Material type is crucial. Different materials require specific cutter characteristics. For instance, cutting metals often needs harder materials. Wood can be more forgiving. Remember that using the wrong cutter can lead to poor finishes or tool damage.

Tool geometry is another important aspect. Cutter shape influences the cutting action. A flat end cutter works well for surface finishing. In contrast, a ball end cutter allows for intricate designs. Consider your project needs carefully. Test results may differ from expectations.

**Tips:** Always assess the cutter's intended use. Mismatched tools can waste time and resources. Keep an eye on wear and tear, particularly for frequent use.

Additionally, cutter diameter impacts precision and speed. Larger diameter cutters remove material quickly but may lack detail. Smaller ones provide finesse but can stall. Strike a balance according to your project requirements.

Reflections on past projects can guide your choices. Note what worked and what didn’t. A simple mistake can lead to significant issues. Adjust based on those experiences for better outcomes.

Choosing the Right Milling Cutter: Factors to Consider

Compatibility of Milling Cutters with Different Machines

Choosing the right milling cutter involves understanding machine compatibility. Various milling machines have specific requirements. Using a cutter not designed for a machine can lead to poor performance or damage. Reports show that mismatched tools can reduce efficiency by up to 30%. This affects both production speed and quality.

Different materials require different cutters. For example, hard materials like steel need robust cutters. Soft materials may need finer teeth for a smoother finish. However, using the wrong cutter can cause excessive wear. This can double replacement costs and extend downtime.

Compatibility is not just about size. It's also about the type of operation. For instance, face milling requires a different cutter design than slab milling. Understanding these differences is crucial. Research found that nearly 25% of tool-related failures are due to compatibility issues. Choosing the right cutter enhances productivity. But this choice can be complicated. Regular reviews of compatibility will prevent mishaps and improve overall machine longevity.

Tips for Maintenance and Care of Milling Cutters

Taking care of milling cutters

is crucial for their longevity. Regular maintenance helps in achieving consistent performance. A

clean cutter works better and produces finer results. Start by wiping the cutter with a soft cloth to remove chips and debris.

Avoid harsh chemicals; they can damage the tool surface.

Inspecting the cutter regularly is essential.

Look for wear or dullness. A worn cutter can ruin your project. If you notice any issues,

consider sharpening or replacing the cutter. Store milling cutters in a dry, clean place.

This can prevent rust and damage over time. Using protective cases or racks is a smart choice.

It's easy to overlook these details. Life gets busy, and maintenance can slip your mind.

But neglecting your tools leads to bigger problems down the line.

Evaluate your routine and make adjustments as needed. Remember, a little care goes a long way.

Keep your milling cutters sharp and ready for action.

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us