Top Uses and Benefits of Circular Blades for Precision Cutting Tasks

In the realm of precision cutting tasks, circular blades have emerged as essential tools across a wide array of industries, including manufacturing, woodworking, and textiles. According to a market research report by Global Industry Analysts, the global circular saw market is expected to reach over $1.4 billion by 2027, driven by the growing demand for efficient cutting solutions in various sectors. This transformative technology not only enhances productivity but also ensures accuracy and consistency, vital in processes that require meticulous attention to detail.

The versatility of circular blades makes them suitable for a multitude of applications, from processing materials such as wood and metal to cutting fabrics and plastics. A thorough examination of industry practices reveals that companies leveraging advanced circular blade technologies achieve significant reductions in material waste and operational costs. Additionally, the ability to produce clean cuts with minimal burr formation has empowered businesses to maintain high standards of quality control. As the demand for precision cutting tasks escalates, understanding the benefits and uses of circular blades will be paramount for professionals seeking to optimize their workflows and elevate their manufacturing capabilities.

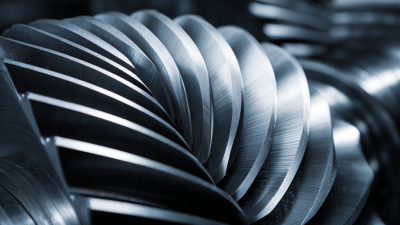

Understanding Circular Blades: Types and Design Features

Circular blades are essential tools in various industries, particularly for precision cutting tasks. Understanding the different types and design features of circular blades can enhance operational efficiency and output quality. Circular blades come in various shapes, sizes, and materials, each tailored for specific applications. Common types include high-speed steel (HSS) blades, carbide-tipped blades, and diamond blades. According to a report by Grand View Research, the global market for circular saw blades is projected to reach $2.83 billion by 2025, highlighting the critical role they play in industries such as woodworking, metalworking, and manufacturing.

The design features of circular blades significantly influence their performance and durability. Blade diameter, tooth geometry, and material composition are crucial factors that affect cutting speed, precision, and longevity. For example, blades with a higher tooth count provide smoother cuts and are often used for fine woodworking projects, while those with fewer teeth are ideal for faster, rough cuts in thicker materials. Additionally, advancements in technology have led to innovations like laser-cutting edges that deliver superior precision and reduce the risk of chipping. As per Market Research Future, the demand for advanced blade designs, including those with specialized coatings that enhance heat resistance and reduce friction, is on the rise, reflecting the industry's pursuit of higher productivity and lower operational costs.

Advantages of Using Circular Blades in Precision Cutting Tasks

Circular blades are renowned for their precision and efficiency in cutting tasks across various industries. One of the primary advantages of using circular blades is their ability to provide clean and uniform cuts. This precision is crucial in fields such as woodworking and metal fabrication, where the integrity of the material is paramount. The consistent edge provided by circular blades helps reduce the amount of reworking needed, thereby saving time and resources.

Another significant benefit of circular blades is their versatility. They can be used on a wide range of materials, including wood, plastic, and soft metals. This adaptability makes them an essential tool in workshops and industrial settings. Additionally, the design of circular blades minimizes friction during cutting, which not only extends the blade's lifespan but also enhances the overall cutting experience by reducing heat generation. As a result, users can achieve high-quality results with minimal wear and tear on both the blade and the equipment used in the cutting process.

Applications of Circular Blades Across Various Industries

Circular blades are essential tools widely utilized across various industries due to their precision and efficiency in cutting tasks. In the woodworking sector, for instance, these blades enable carpenters and manufacturers to make clean, accurate cuts in different materials, including plywood and hardwood. This level of precision not only enhances the quality of the finished products but also reduces material waste, making the production process more sustainable.

In the packaging industry, circular blades play a critical role in cutting through various materials such as cardboard and plastic films. The speed and accuracy of these blades facilitate high-volume production, ensuring that packaging processes remain efficient while maintaining safety standards. Furthermore, in the textile industry, circular blades are used to cut fabric layers, providing the necessary precision for intricate designs and patterns. The versatility and reliability of these blades contribute significantly to the productivity and quality control in these sectors.

Maintenance and Care Tips for Enhancing Blade Longevity

Maintaining circular blades is crucial for ensuring their precision and longevity. Regular cleaning is a key aspect of blade maintenance. After each use, remove any debris, resin, or built-up material that may cling to the blade. A soft brush or cloth can effectively clean the surface without damaging the edges. For more stubborn residues, using a mixture of mild soap and water can help, but it’s essential to dry the blade thoroughly afterward to prevent any rust or corrosion.

Proper storage is another important factor in extending the life of circular blades. Keeping blades in a protective case or sheath will not only shield them from physical damage but also help maintain their sharpness. Additionally, consider storing blades in a dry environment, as moisture can lead to deterioration. Regularly inspecting blades for any signs of wear or damage is also advisable; this proactive approach can help identify issues before they impact performance, allowing for timely repairs or replacements.

Top Uses and Benefits of Circular Blades for Precision Cutting Tasks

| Application |

Benefit |

Material Compatibility |

Maintenance Tips |

| Woodworking |

Provides clean and precise cuts |

Solid wood, plywood |

Regularly clean blade and check alignment |

| Metal Cutting |

Excellent for cutting metal sheets and tubing |

Aluminum, steel |

Use cutting oil to reduce wear |

| Plastic Fabrication |

Minimizes melting and chipping |

Acrylic, PVC |

Keep blades sharp to prevent melting |

| Textile Cutting |

Delivers precise cuts for clean edges |

Fabric, leather |

Store blades dry and free from dust |

| Food Preparation |

Ensures uniform slices for presentation |

Fruits, vegetables, cooked meats |

Regularly sharpen and sanitize |

Safety Measures When Working with Circular Blades

When working with circular blades, safety should always be the top priority, as improper handling can lead to serious injuries. According to a report by the U.S. Bureau of Labor Statistics, approximately 30,000 to 40,000 workers suffer from severe lacerations in the workplace each year, with a significant portion attributed to cutting tools. To mitigate these risks, it is crucial to employ appropriate safety measures. Always ensure that the blade is sharp and well-maintained; dull blades are more likely to slip and cause accidents. Personal protective equipment (PPE) such as gloves, goggles, and aprons should be worn to protect against potential hazards.

When utilizing circular blades, it’s essential to follow proper operating procedures. Before starting any cutting task, inspect your equipment for any defects or damage. Ensure that the work area is clean and free from clutter to prevent accidental injuries. Employing a sturdy work surface can limit the chances of slipping during operation. Additionally, educating team members on the correct techniques for handling and using circular blades can drastically reduce workplace injuries.

Tip: Always unplug or disengage the circular saw before changing blades or making adjustments. This simple action can prevent unintentional start-ups that might lead to serious harm. Furthermore, regularly review and adhere to safety guidelines outlined by relevant occupational safety organizations to foster a culture of safety within the workplace.

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us