10 Reasons Why Polished Tungsten Plate is the Best Choice for High Performance Applications

In the competitive landscape of high-performance applications, the selection of materials can significantly influence the efficiency and effectiveness of an operation. Among the various options available, the polished tungsten plate has emerged as a standout choice, thanks to its remarkable properties such as high density, excellent thermal conductivity, and exceptional resistance to wear and corrosion. According to a market analysis by Smith & Associates, the demand for polished tungsten products is projected to grow at a CAGR of 12% over the next five years, reflecting the increasing reliance on tungsten in advanced manufacturing sectors.

Expert insights further substantiate the advantages of polished tungsten plates. Dr. Emily Zhao, a leading materials scientist at the International Tungsten Association, emphasizes, “The use of polished tungsten plates in high-performance applications not only enhances operational efficiency but also reduces maintenance costs, making it a wise investment for industries aiming for longevity and reliability." This statement encapsulates why polished tungsten plates are not simply favored for their performance characteristics, but are also seen as a strategic asset for companies looking to optimize their material choices in demanding environments.

Key Characteristics of Polished Tungsten Plates for Optimal Performance

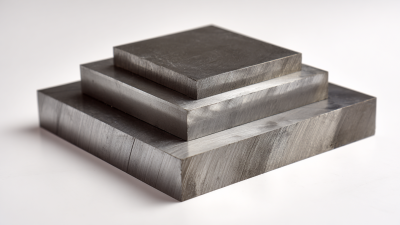

Polished tungsten plates are increasingly recognized for their superior performance in high-stress applications, thanks to their unique characteristics. Firstly, tungsten has an exceptional melting point, which is the highest of all metals, allowing it to maintain its structural integrity in extreme temperatures. This makes polished tungsten plates ideal for environments where heat resistance is crucial, such as aerospace and military applications. Moreover, the density of tungsten contributes to its high durability, ensuring that polished plates can withstand significant mechanical stress without deformation or damage.

Polished tungsten plates are increasingly recognized for their superior performance in high-stress applications, thanks to their unique characteristics. Firstly, tungsten has an exceptional melting point, which is the highest of all metals, allowing it to maintain its structural integrity in extreme temperatures. This makes polished tungsten plates ideal for environments where heat resistance is crucial, such as aerospace and military applications. Moreover, the density of tungsten contributes to its high durability, ensuring that polished plates can withstand significant mechanical stress without deformation or damage.

Another key characteristic of polished tungsten plates is their outstanding hardness. With a hardness rating that surpasses many other metals, polished tungsten is less likely to wear down or corrode over time. This durability translates into longer service life, reducing the need for frequent replacements and maintenance. Additionally, the polished surface enhances the material's aesthetic appeal while facilitating easy cleaning, making it suitable not only for industrial use but also for applications where visual quality is essential. The combination of high melting point, density, and hardness positions polished tungsten plates as the optimal choice for high-performance demanding scenarios.

Mechanical Strength and Durability: Why Tungsten Excels in Demanding Environments

Polished tungsten plates are increasingly recognized for their exceptional mechanical strength and durability, making them an ideal choice for high-performance applications. Tungsten, renowned for its high melting point and remarkable hardness, can withstand extreme temperatures and stress that would compromise other materials. This characteristic is crucial in demanding environments such as aerospace, military applications, and specialized industrial settings, where equipment must endure rigorous operations without failure.

Furthermore, tungsten's density contributes to its ability to absorb shock and resist wear, enhancing its performance in applications that involve heavy-duty usage. The polished surface finish not only increases the aesthetic appeal but also minimizes friction, reducing wear on interacting components. As industries continue to prioritize reliability in challenging conditions, tungsten's mechanical properties position it as a material of choice for engineers and manufacturers looking to push the limits of performance and longevity in their products.

Corrosion Resistance: Ensuring Longevity in Harsh Conditions

Polished tungsten plates have emerged as a preferred choice in high-performance applications, primarily due to their exceptional corrosion resistance. In environments exposed to extreme conditions such as high temperatures and aggressive chemicals, tungsten's ability to withstand oxidation and wear becomes crucial. According to a report by the International Tungsten Industry Association (ITIA), tungsten exhibits a minimal corrosion rate compared to other metals, ensuring its longevity and reliability in applications like aerospace, electronics, and heavy machinery.

One of the main advantages of polished tungsten is its unique microstructure, which aids in enhancing surface integrity. This feature not only increases its resistance against pitting and crevice corrosion but also provides a sleek finish that is essential for maintaining functionality in high-stakes environments. A recent study from the Materials Research Society highlights that polished tungsten can retain mechanical strength at temperatures reaching 500°C, making it an optimal candidate for applications requiring durability under thermal stress.

Tips for selecting polished tungsten plates include assessing the specific environmental conditions they will face and considering additional protective coatings for extreme cases. Additionally, sourcing from reputable suppliers who provide certifications and material testing results is vital to ensure that the tungsten meets the desired specifications.

Thermal Conductivity: Enhancing Efficiency in High-Temperature Applications

Polished tungsten plates are increasingly recognized for their exceptional thermal conductivity, making them ideal for high-performance applications in industries such as aerospace, electronics, and manufacturing. With thermal conductivity exceeding 170 W/m·K, tungsten significantly surpasses materials like aluminum and copper, providing superior heat dissipation capabilities. This property is crucial for high-temperature environments where efficient heat transfer can prevent overheating and enhance operational efficiency.

Additionally, the robustness of tungsten ensures not only high thermal performance but also durability under extreme conditions. According to a report from the International Journal of Thermal Sciences, tungsten maintains its thermal conductivity at temperatures above 2000°C, which is a pivotal factor for components that operate in such challenging atmospheres. By utilizing polished tungsten plates, businesses can achieve longer operational lifespans and reduced downtime, translating to cost savings and increased productivity. As industries continue to push the boundaries of performance, the benefits of polished tungsten in applications requiring high thermal efficiency are becoming increasingly evident.

10 Reasons Why Polished Tungsten Plate is the Best Choice for High Performance Applications

Thermal Conductivity: Enhancing Efficiency in High-Temperature Applications

Cost-Effectiveness: Balancing Performance and Budget in Long-Term Usage

Polished tungsten plates have emerged as a leading choice for high-performance applications, particularly due to their cost-effectiveness when evaluated over long-term usage. According to a report by Market Research Future, the global tungsten market is projected to reach USD 3 billion by 2023, driven by an increasing demand for materials that offer both strength and longevity. Polished tungsten plates not only exhibit exceptional hardness and corrosion resistance but also maintain their performance over extended periods, reducing the need for frequent replacements. This durability is a key factor that contributes to their cost-effectiveness in industries such as aerospace and manufacturing.

In addition, a study conducted by the International Journal of Engineering Research found that utilizing polished tungsten plates can lead to a reduction in operational costs by up to 30% when compared to traditional materials. This significant saving stems from lower maintenance requirements and reduced downtime associated with equipment failure. By investing in polished tungsten, businesses can achieve an optimal balance between performance and budget, ensuring that they meet their operational demands while also maximizing their return on investment.

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

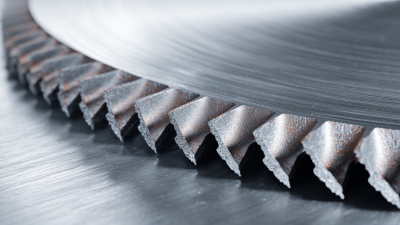

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us