Top 10 Precision Tools for Accurate Measurement and Cutting in 2023

In the world of craftsmanship and construction, the importance of precision cannot be overstated. As the renowned expert in precision measurement, Dr. Samantha Gordon, once said, “The right tools are essential for achieving accuracy; without precision tools, all measurements are merely estimates.” This belief underscores the critical reliance on high-quality precision tools for professionals across a variety of fields, from woodworking to engineering. In 2023, advancements in technology continue to enhance the capabilities of these essential instruments, allowing for even greater accuracy and efficiency in both measurement and cutting.

As we delve into the Top 10 Precision Tools for Accurate Measurement and Cutting in 2023, we highlight the various instruments that stand at the forefront of innovation and reliability. These tools not only embody durability and precision but also integrate modern features that cater to the evolving needs of craftsmen and engineers alike. By leveraging the latest advancements in precision tool design and functionality, professionals can optimize their workflows, ensuring that every project is executed with the utmost accuracy.

Overview of Precision Tools for Accurate Measurement and Cutting

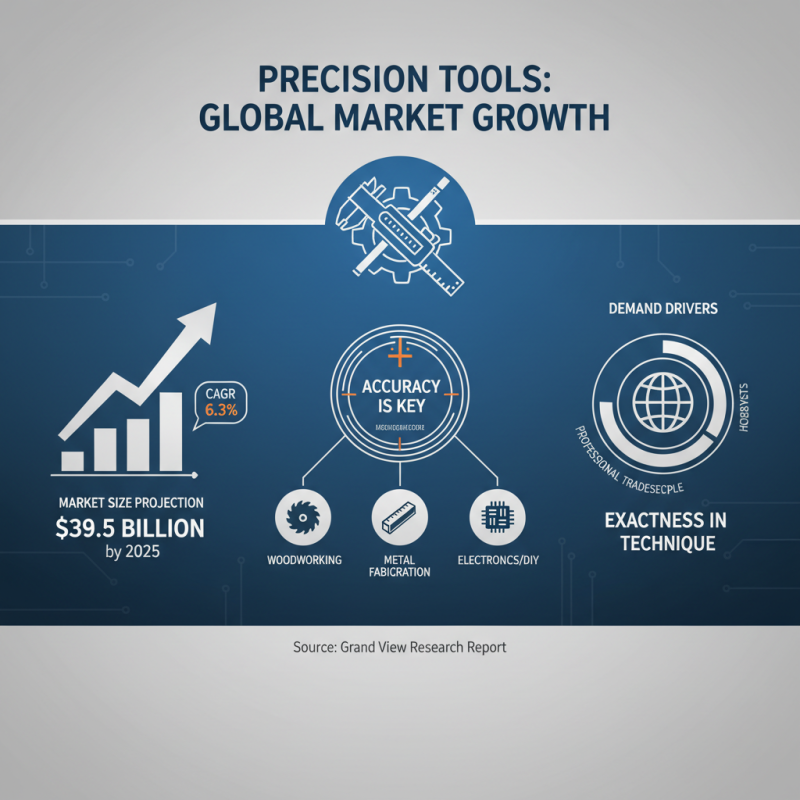

In the realm of precision tools, accuracy in measurement and cutting is paramount for a variety of applications, from woodworking to metal fabrication. According to a report by Grand View Research, the global precision tool market size is projected to reach $39.5 billion by 2025, growing at a compound annual growth rate (CAGR) of 6.3%. This growth reflects the increasing demand for advanced tools that ensure exactness in technique, crucial for both professional tradespeople and hobbyists alike.

Among the essential precision tools are digital calipers, micrometers, and laser measurement devices, each designed to deliver exceptional accuracy. Digital calipers, for instance, can measure components with incredible precision, often within 0.01mm. Similarly, laser measuring tools have revolutionized the way distances are calculated, providing precision readings within millimeters over significant distances, which is particularly beneficial in construction and interior design. A study from the National Institute of Standards and Technology highlighted that using high-precision measurement tools can reduce errors by up to 47%, underscoring the importance of selecting the right equipment to enhance operational efficiency and quality assurance in various industries.

Key Features to Consider When Choosing Precision Tools

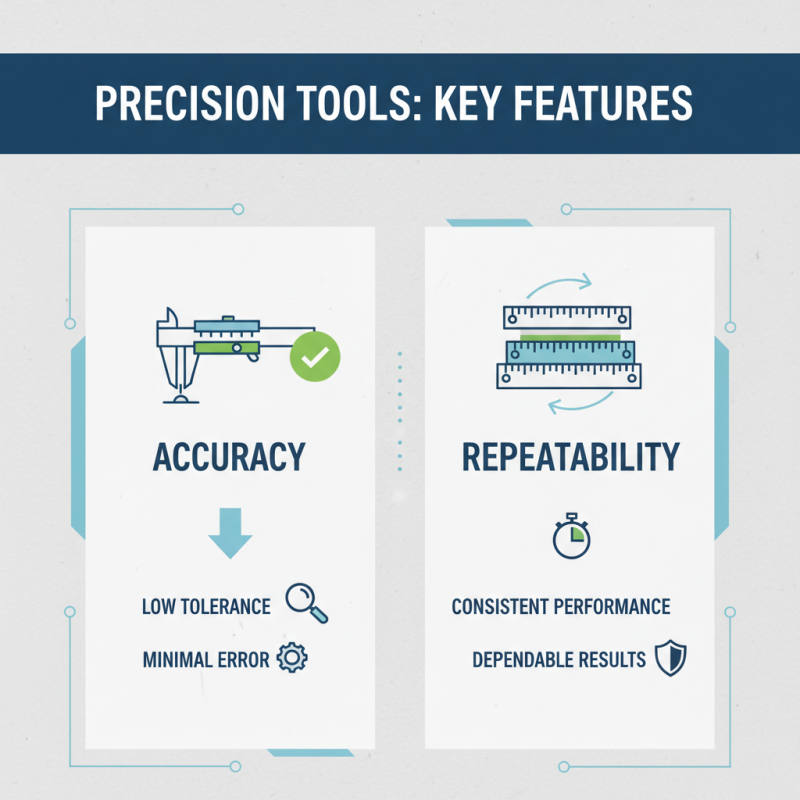

When selecting precision tools for accurate measurement and cutting, several key features must be taken into account. First and foremost is the tool’s accuracy, which is usually specified in terms of tolerance levels. A tool with a lower tolerance indicates a higher level of precision, making it crucial for tasks where even minor errors can have significant consequences. Additionally, look for tools that offer repeatability—a quality that ensures consistent performance over multiple uses. This feature is particularly valuable for professionals and hobbyists alike who require dependable results in both repeat tasks and intricate projects.

Another important aspect is the ease of use and ergonomics of the tool. A well-designed tool can significantly reduce user fatigue, improving workflow efficiency during extended periods of use. Features such as intuitive controls, comfortable grips, and clear measurement indicators can enhance the user experience and accuracy of the task at hand. Finally, consider the material and construction of the tools, as these factors influence durability and overall performance. High-quality materials resist wear and tear, ensuring that your precision tools remain reliable over time, even in demanding environments. By focusing on these key features, you can choose the right precision tools that cater to your specific needs in 2023.

Top Precision Measuring Tools for Professionals in 2023

When it comes to precision measuring tools for professionals in 2023, accuracy and reliability are paramount. From construction sites to manufacturing floors, the right tools can significantly enhance productivity and ensure superior quality in every project. Professionals must consider tools that not only provide precise measurements but are also easy to use and durable, ensuring they can withstand the demands of the job.

A highly recommended approach is to invest in electronic calipers and micrometers, which offer quick and exact measurements for small parts. Laser distance meters are also gaining traction, providing instant readings over long distances without the need for cumbersome measuring tapes. These digital tools reduce human error and improve efficiency, making them invaluable for professionals who rely heavily on precision.

Tips: When selecting precision measuring tools, always prioritize those with clear displays and intuitive interfaces to save time and minimize errors. Regular calibration is also essential to maintain accuracy, so set a schedule to check your tools periodically. Finally, consider the specific needs of your profession; for example, woodworking might require different tools compared to metalworking, so tailor your toolkit accordingly to fit your requirements perfectly.

Best Cutting Tools for Precision and Accuracy in Various Applications

Precision and accuracy are crucial in various applications, from woodworking to metal fabrication, and having the right cutting tools can make all the difference. In 2023, several cutting tools stand out for their exceptional performance and reliability. For instance, laser cutters offer unparalleled precision, allowing users to achieve intricate designs with sharp finishes, making them ideal for both professional and hobbyist use. Additionally, CNC machines are revolutionizing the industry by automating cutting processes, ensuring consistent results and minimizing human error.

Another vital category includes manual cutting tools, such as precision knives and handheld saws, which are essential for detailed work. These tools provide the ability to control the cutting depth and angle, making them perfect for delicate materials where precision is paramount. Moreover, measuring tools such as calipers and micrometers play a fundamental role in ensuring that cuts are made accurately, allowing users to gauge dimensions precisely before executing their work. Emphasizing the importance of combining measuring instruments with cutting tools enhances overall project quality and efficiency, ensuring that every cut meets the desired specifications.

Top 10 Precision Tools for Accurate Measurement and Cutting in 2023

This chart illustrates the popularity of various precision tools used for accurate measurement and cutting in various applications as of 2023. The data reflects the percentage of users who prefer each tool based on usage metrics.

Innovative Technologies Enhancing Precision Tools in 2023

In 2023, precision tools have seen significant advancements through innovative technologies that enhance their accuracy and usability. Smart sensors are at the forefront of this transformation, allowing for real-time adjustments based on environmental factors and user input. These sensors not only increase measurement precision but also provide users with instant feedback, ensuring that every cut or measurement is accurate and tailored to specific requirements. The integration of augmented reality (AR) technology further allows users to visualize their adjustments and measurements digitally, bridging the gap between the physical and digital worlds.

Moreover, automation plays a crucial role in revolutionizing precision tools this year. By incorporating machine learning algorithms, tools can learn from previous tasks and refine their performance over time. This means that users can achieve consistent results with minimal effort, reducing the likelihood of human error. The emergence of ergonomic designs combined with wireless connectivity also enables users to operate tools comfortably and efficiently, enhancing their overall experience. As technology continues to evolve, precision tools are becoming increasingly indispensable for both professional and DIY environments, enabling users to execute complex tasks with remarkable accuracy.

Top 10 Precision Tools for Accurate Measurement and Cutting in 2023

| Tool |

Type |

Accuracy |

Innovative Feature |

Price Range (USD) |

| Digital Caliper |

Measuring |

± 0.02 mm |

Bluetooth Connectivity |

50 - 150 |

| Laser Distance Measurer |

Measuring |

± 1.5 mm |

App Integration |

60 - 200 |

| Precision Router |

Cutting |

± 0.05 mm |

Variable Speed Control |

150 - 400 |

| Digital Angle Finder |

Measuring |

± 0.1° |

Backlit Display |

25 - 80 |

| Pocket Hole Jig |

Joining |

N/A |

Quick Adjust Features |

30 - 120 |

| CNC Router |

Cutting |

± 0.1 mm |

Software Integration |

1000 - 5000 |

| Laser Cutter |

Cutting |

± 0.01 mm |

High Precision Beam |

500 - 3000 |

| Torpedo Level |

Measuring |

± 0.5 mm/m |

Magnetic Base |

20 - 60 |

| Measuring Tape |

Measuring |

N/A |

Self-locking Mechanism |

10 - 50 |

| Protractor |

Measuring |

± 1° |

Dual Scale |

5 - 25 |

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us