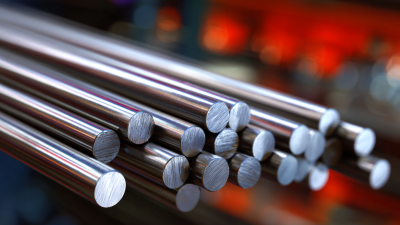

Why Tungsten Carbide Round Bars Are the Best Choice for Heavy Duty Applications

In the world of heavy-duty applications, the choice of materials can drastically impact performance and longevity. Recent industry reports indicate that Tungsten Carbide Round Bars have become increasingly preferred due to their unparalleled hardness and wear resistance. According to a study published by the International Journal of Engineering Materials, Tungsten Carbide Round Bars exhibit a hardness rating of 1600-2000 HV, making them significantly more durable than traditional materials. This exceptional toughness is essential for industries ranging from mining to aerospace, where equipment is subjected to extreme conditions.

Dr. Michael Henderson, a leading expert in materials engineering, emphasizes the importance of selecting the right material for robust applications: “The use of Tungsten Carbide Round Bars not only enhances operational efficiency but also reduces downtime and maintenance costs.” His insights highlight the growing trend towards adopting these bars in applications that demand resilience. The combination of superior mechanical properties and a lower total cost of ownership makes Tungsten Carbide Round Bars the ideal choice for engineers and manufacturers looking to optimize their operations in challenging environments. As this material continues to dominate heavy-duty applications, understanding its benefits becomes imperative for industry stakeholders.

Advantages of Tungsten Carbide in High-Stress Environments

Tungsten carbide round bars are increasingly recognized for their exceptional performance in high-stress environments, making them an ideal choice for heavy-duty applications. The unique properties of tungsten carbide, including its remarkable hardness and wear resistance, allow it to endure extreme pressures and temperatures. These characteristics are particularly relevant in industries such as defense and aerospace, where materials must sustain extreme conditions, such as those faced by hypersonic vehicles traveling at speeds exceeding five times the speed of sound.

In addition to its robustness, tungsten carbide plays a critical role in global defense systems and advanced manufacturing technologies. Its ability to maintain structural integrity under high-stress scenarios ensures reliability and longevity of components used in challenging settings. This makes tungsten carbide not only advantageous for manufacturing tools and components but also essential in applications where failure is not an option. The growing reliance on tungsten carbide in various high-performance applications highlights its indispensable role in modern technology and industrial innovation.

Comparative Durability: Tungsten Carbide vs. Traditional Materials

When it comes to heavy-duty applications, the choice of materials can significantly influence performance and longevity. Tungsten carbide round bars have emerged as a superior alternative to traditional materials like steel and aluminum. According to the International Tungsten Industry Association, tungsten carbide's hardness is approximately 10 times greater than that of steel, making it an exceptional choice for environments that demand resilience against wear and tear. This durability translates into lower maintenance costs and extended service life, which are critical factors in industrial settings.

Moreover, a study conducted by ASTM International reported that tungsten carbide exhibits outstanding resistance to heat and pressure, allowing it to maintain structural integrity in extreme conditions. Traditional materials often struggle with deformation and wear over time, leading to frequent replacements and increased downtime. In contrast, tungsten carbide round bars can withstand temperatures exceeding 1,000°C and resist corrosive influences, making them ideal for demanding applications in sectors such as mining, machining, and aerospace. As industries continue to seek materials that enhance efficiency and reduce operational costs, tungsten carbide stands out as a reliable and cost-effective solution.

Applications of Tungsten Carbide Round Bars in Heavy Machinery

Tungsten carbide round bars are increasingly recognized for their exceptional performance in heavy machinery applications, significantly contributing to the efficiency and durability of various industrial processes. As the global carbide tools market is projected to grow from $11.54 billion in 2024 to $18.41 billion by 2032, with a CAGR of 6.0%, the demand for high-quality materials such as tungsten carbide is expected to rise. These round bars are vital in industries that require robust components, such as mining, construction, and metalworking, where the need for dependable and high-strength materials is paramount.

The applications of tungsten carbide round bars in heavy machinery are diverse. They are ideal for critical components like rollers, cutting tools, and grinding equipment, where wear resistance and toughness are essential. For instance, in high-pressure grinding roller (HPGR) systems, the use of carbide studs can dramatically extend the lifespan of the machinery, enhancing energy efficiency and reducing operational downtimes. Such advancements in machining technology and materials underscore the growing attractiveness of tungsten carbide solutions in meeting the evolving market needs of heavy-duty applications.

Applications of Tungsten Carbide Round Bars in Heavy Machinery

Cost-Effectiveness of Tungsten Carbide in Long-Term Use

Tungsten carbide round bars are revered in heavy-duty applications not only for their exceptional strength and durability but also for their cost-effectiveness in the long run. These bars are designed to withstand extreme wear and tear, making them an ideal choice for industries that require reliable performance under challenging conditions. While the initial investment may be higher than alternatives, the longevity and reduced maintenance costs associated with tungsten carbide result in significant savings over time.

When considering tungsten carbide for your heavy-duty applications, remember that its hardness contributes to lower frequency of replacements. This means fewer interruptions in operations, ultimately enhancing productivity. Investing in quality materials like tungsten carbide can significantly reduce overall costs by minimizing downtime and maintenance needs.

Tips: Always assess the specific demands of your application before selecting materials. Consult with suppliers to determine the best specifications for your needs. Additionally, consider the total cost of ownership rather than just the upfront price to truly appreciate the value of tungsten carbide round bars.

Manufacturing Process and Quality Control of Tungsten Carbide Bars

The manufacturing process of tungsten carbide round bars is critical to their performance in heavy-duty applications. The process begins with the careful selection of high-quality raw materials, typically tungsten and carbon powders. These powders are mixed in precise ratios and then subjected to high pressures and temperatures in a process known as sintering. This step is vital, as it transforms the powders into a solid form with exceptional hardness and durability, making the bars highly resistant to wear and tear.

Quality control is another essential aspect that ensures tungsten carbide bars meet industry standards. Rigorous testing procedures, including density checks and hardness measurements, are performed at various stages of production. This careful monitoring helps identify any inconsistencies and guarantees that the final product can withstand the demands of heavy-duty applications.

Tips: When selecting tungsten carbide bars, always inquire about the manufacturing process and quality control measures. Look for suppliers who provide detailed information about their testing protocols, as this ensures you're receiving a product that truly meets the necessary specifications for robust performance. Additionally, consider the specific application requirements to choose the right grade of tungsten carbide for optimal results.

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us