Ultimate Guide to Understanding the Benefits and Applications of Polished Tungsten Plates in Modern Manufacturing

In the ever-evolving landscape of modern manufacturing, polished tungsten plates have emerged as essential materials, noted for their exceptional durability and versatility. According to a recent report by Grand View Research, the global tungsten market is projected to reach USD 2.5 billion by 2027, underscoring the growing demand for high-performance materials across various industries, including aerospace, electronics, and medical sectors.

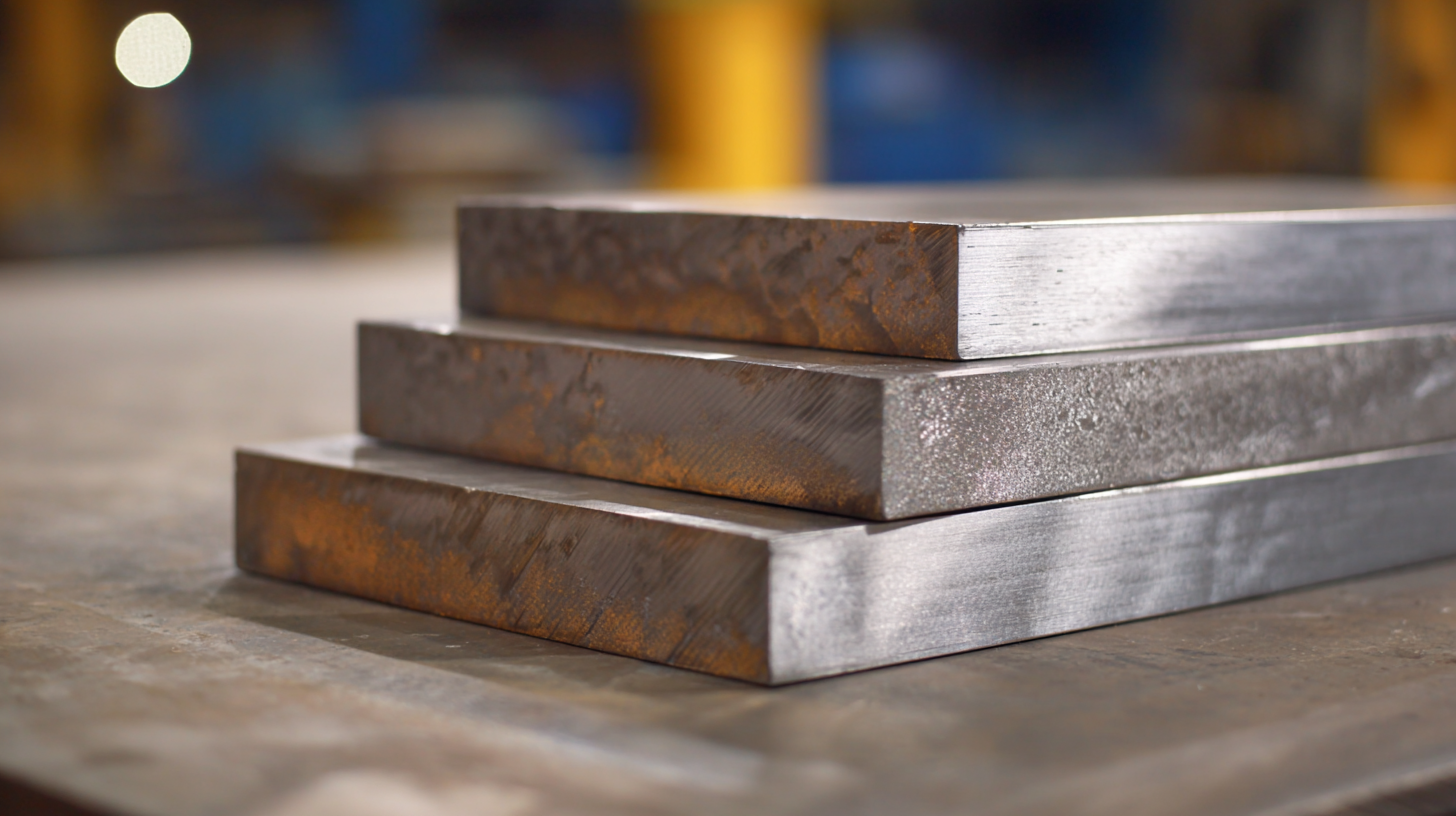

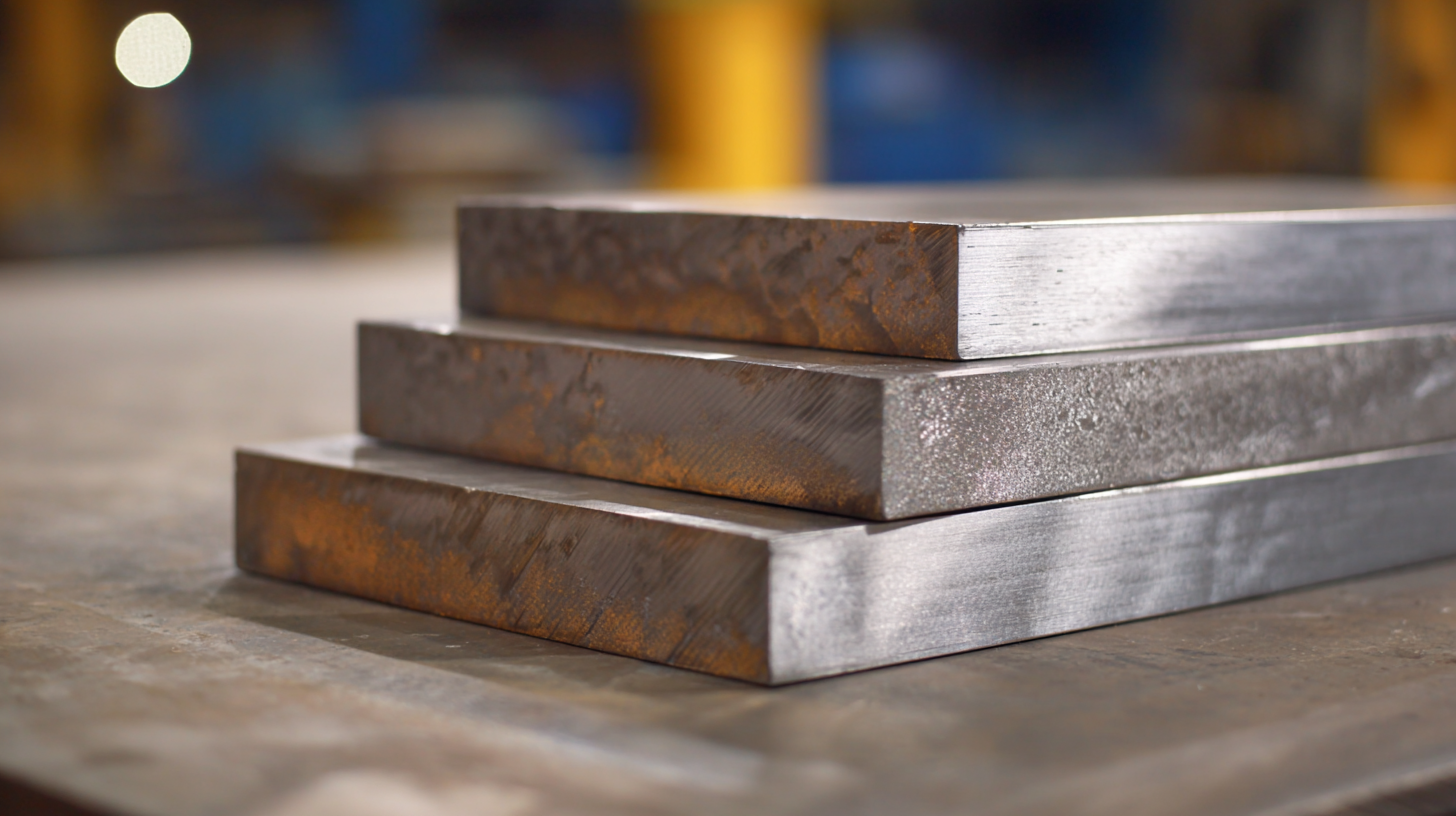

Polished tungsten plates stand out due to their remarkable properties, such as high density, excellent thermal conductivity, and superior resistance to wear and corrosion. These attributes make them ideal for applications ranging from high-temperature environments to precision components in cutting-edge technological innovations.

As manufacturers seek to optimize performance and enhance product longevity, understanding the benefits and applications of polished tungsten plates becomes increasingly vital for maintaining competitive advantages in the marketplace.

Polished tungsten plates stand out due to their remarkable properties, such as high density, excellent thermal conductivity, and superior resistance to wear and corrosion. These attributes make them ideal for applications ranging from high-temperature environments to precision components in cutting-edge technological innovations.

As manufacturers seek to optimize performance and enhance product longevity, understanding the benefits and applications of polished tungsten plates becomes increasingly vital for maintaining competitive advantages in the marketplace.

Advantages of Polished Tungsten Plates in Manufacturing Processes

Polished tungsten plates have steadily gained recognition in modern manufacturing, primarily due to their unique properties and advantages. These plates are renowned for their exceptional hardness and high melting point (over 3,400°C), making them ideal for applications requiring durability and resilience. According to a recent report by Grand View Research, the global tungsten market is anticipated to reach USD 3.81 billion by 2025, largely driven by the increased demand for polished tungsten plates in sectors like aerospace and automotive manufacturing.

Polished tungsten plates have steadily gained recognition in modern manufacturing, primarily due to their unique properties and advantages. These plates are renowned for their exceptional hardness and high melting point (over 3,400°C), making them ideal for applications requiring durability and resilience. According to a recent report by Grand View Research, the global tungsten market is anticipated to reach USD 3.81 billion by 2025, largely driven by the increased demand for polished tungsten plates in sectors like aerospace and automotive manufacturing.

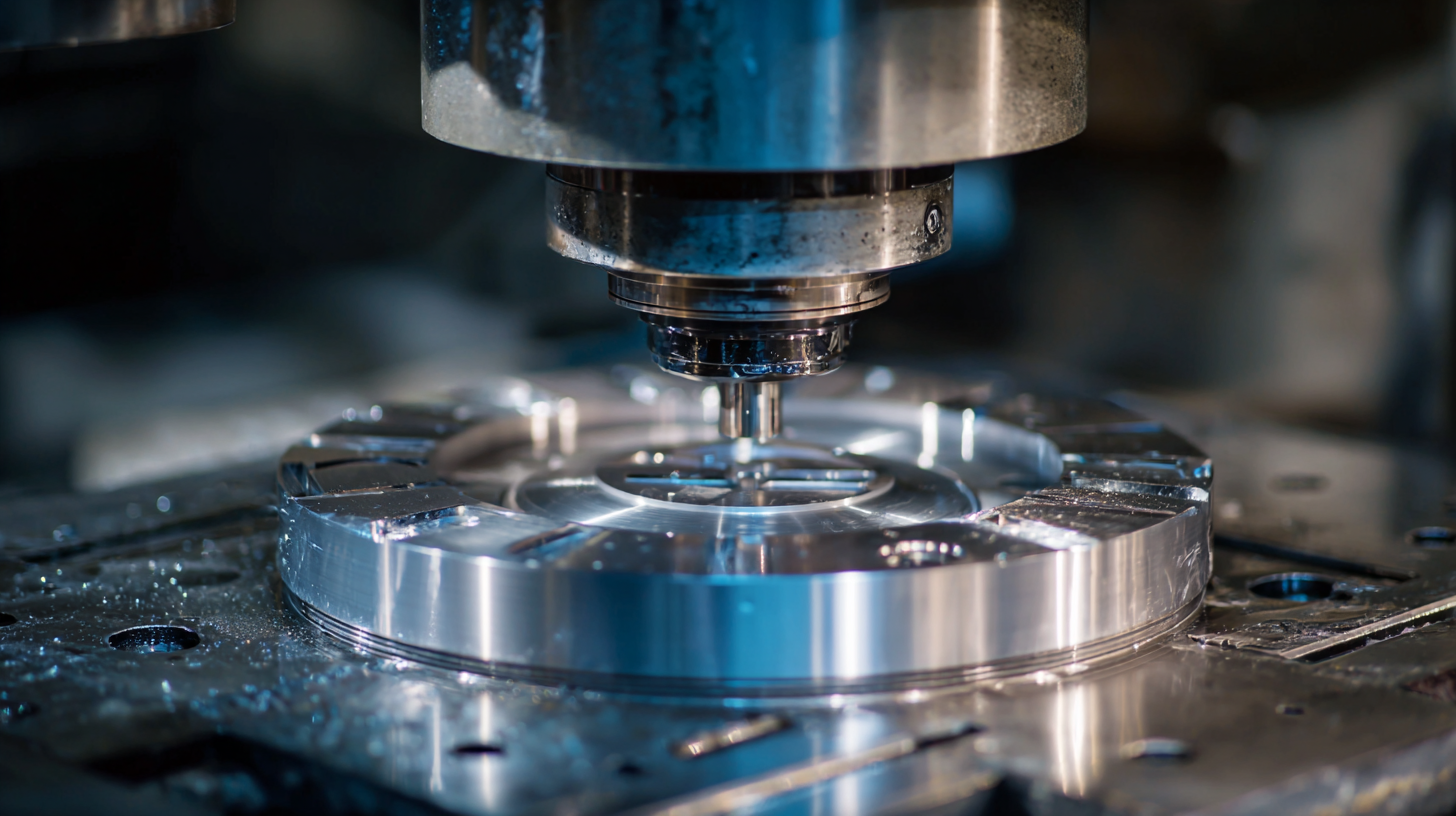

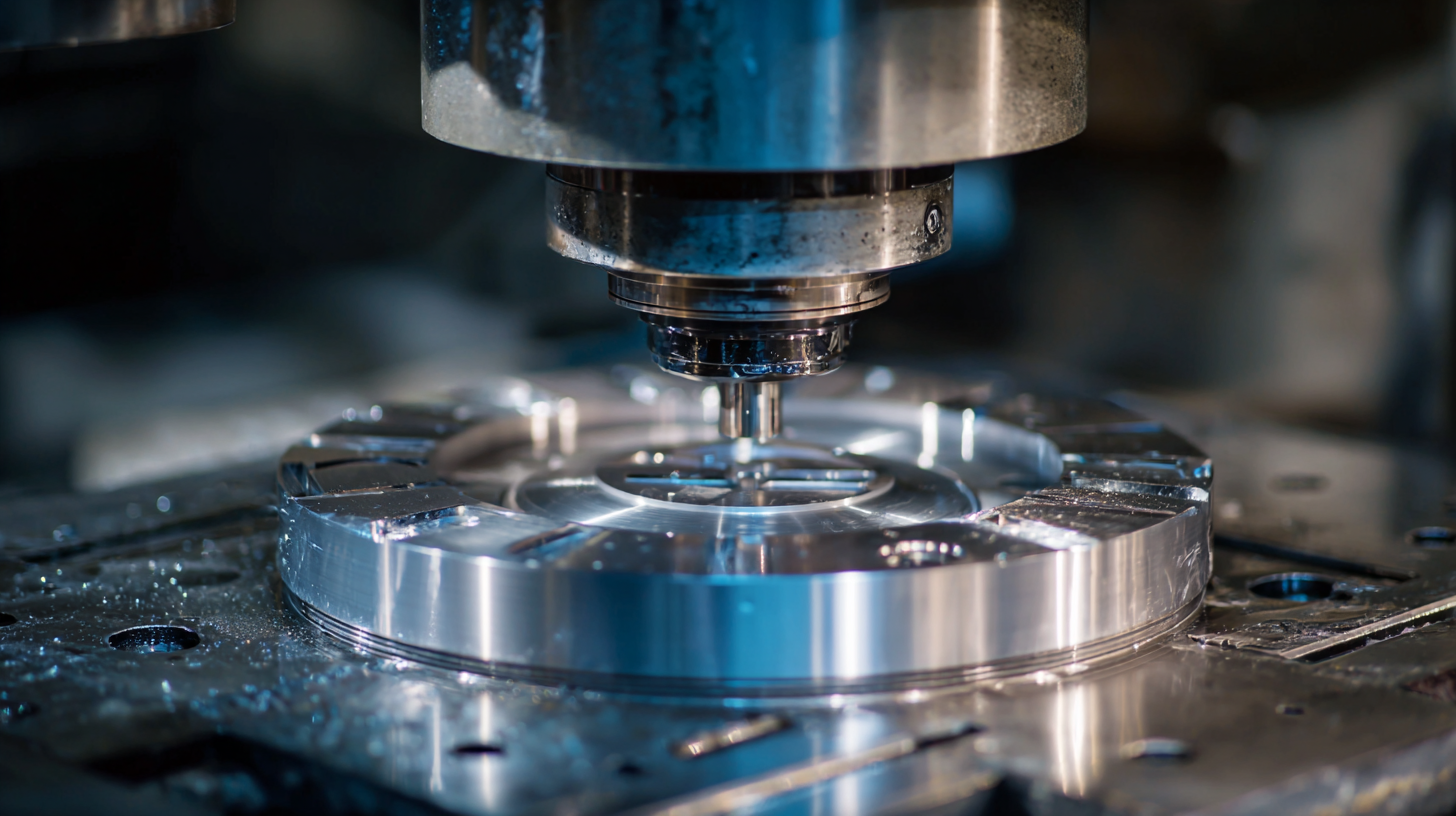

One of the standout benefits of polished tungsten plates is their superior thermal conductivity, which allows them to efficiently dissipate heat during machining processes. This not only extends the life of cutting tools but also enhances precision in manufacturing outputs. Furthermore, polished tungsten's corrosion resistance makes it a preferred choice for components exposed to harsh environments. A study by MarketsandMarkets highlighted that the aerospace sector is projected to grow at a compound annual growth rate (CAGR) of 3.2% from 2020 to 2025, with polished tungsten plates playing a crucial role in the production of high-performance jet engines.

Tip: When working with polished tungsten plates, ensure proper handling and storage to maintain their surface integrity. Utilizing specialized jigs and fixtures can help minimize damage during machining. Additionally, consider implementing advanced machining techniques to leverage the material’s properties fully.

Tip: Regularly check the conditioning and maintenance of tools used with tungsten plates; using the appropriate cooling fluids can significantly enhance tool performance and lifespan.

High-Performance Applications of Polished Tungsten in Industry

Polished tungsten plates have emerged as a critical component in high-performance applications across various industries due to their exceptional mechanical properties. Recent advancements highlighted in research reports reveal that oxidized dispersion strengthened tungsten (ODS-W) alloys demonstrate superior strength and ductility, making them suitable for high-temperature environments. These alloys exhibit excellent creep resistance and microstructural stability, which are essential for aerospace and nuclear applications where materials face extreme conditions.

Furthermore, the exploration of tungsten's interaction with materials like diamond has opened new avenues for innovation in tool manufacturing. A recent Density Functional Theory (DFT) study has provided insights into the graphitization mechanism at the interface between tungsten and diamond surfaces, indicating the potential for enhancing cutting tool performance through advanced material synthesis. The growing interest in high-entropy alloys as an alternative binder in cermets also reflects the industry's commitment to improving mechanical and oxidation properties, indicating a trend towards more durable and adaptable manufacturing solutions. These innovations underscore the versatility and essential role of polished tungsten plates in meeting the demands of modern manufacturing sectors.

Comparative Analysis: Tungsten Plates vs. Other Materials

When comparing tungsten plates to other materials commonly used in manufacturing, the unique properties of tungsten become evident. Tungsten is renowned for its exceptional density, hardness, and resistance to high temperatures. Unlike aluminum or copper, which might be more malleable but lack the strength needed in demanding applications, tungsten plates maintain their structural integrity under extreme conditions. This makes them particularly advantageous in industries such as aerospace and defense, where durability and performance are critical.

Additionally, tungsten plates exhibit excellent thermal and electrical conductivity, rivaling that of copper while offering superior thermal stability. In contrasting tungsten with materials like titanium or steel, we observe that tungsten’s higher melting point enhances its suitability for applications requiring prolonged exposure to heat. Furthermore, unlike softer metals that can deform under stress, tungsten plates retain their shape, ensuring reliability in precision manufacturing processes. As manufacturers increasingly seek materials that can withstand the rigors of modern production, tungsten plates stand out not just for their performance, but also for their long-term cost-effectiveness due to their durability and reduced maintenance needs.

Ultimate Guide to Understanding the Benefits and Applications of Polished Tungsten Plates in Modern Manufacturing - Comparative Analysis: Tungsten Plates vs. Other Materials

| Material |

Density (g/cm³) |

Tensile Strength (MPa) |

Thermal Conductivity (W/m·K) |

Applications |

| Polished Tungsten Plates |

19.25 |

1510 |

173 |

Aerospace, Electronics |

| Stainless Steel |

7.93 |

505 |

16 |

Common Manufacturing, Food Industry |

| Aluminum |

2.70 |

310 |

237 |

Automotive, Aerospace |

| Copper |

8.96 |

210 |

400 |

Electrical, Plumbing |

| Titanium |

4.51 |

900 |

21 |

Aerospace, Medical |

Best Practices for Maintaining and Handling Polished Tungsten Plates

Polished tungsten plates are gaining traction in modern manufacturing due to their exceptional properties, including high density, durability, and resistance to wear. These plates are pivotal in various applications, from aerospace components to advanced medical devices. According to a report by Smithers, the global tungsten market is projected to grow at a CAGR of 5.3% from 2021 to 2026, driven by the increasing demand for high-performance materials in industries such as electronics and automotive.

To ensure optimal performance and longevity of polished tungsten plates, best practices for maintenance and handling are critical. Proper care involves avoiding exposure to harsh chemicals and environmental conditions that could lead to surface degradation. Using specialized storage methods, such as anti-static bags and controlled humidity environments, can further protect these high-value components. As highlighted in the American Society for Metals' guidelines, implementing routine inspections and leveraging non-destructive testing methods can significantly extend the lifecycle of tungsten materials, ensuring they meet rigorous quality and performance standards consistently.

Benefits and Applications of Polished Tungsten Plates in Modern Manufacturing

Future Trends: Innovations in Polished Tungsten Plate Technology

The future of polished tungsten plate technology is bright, driven by innovations that cater to the evolving needs of various industries. One significant trend is the development of advanced coating techniques that enhance the plates' durability and thermal resistance. These innovations not only extend the lifespan of tungsten plates but also improve their performance in high-temperature applications, making them indispensable in aerospace and semiconductor manufacturing.

Another promising direction is the integration of smart technology into polished tungsten plates. By incorporating sensors that monitor temperature, pressure, and wear, manufacturers can gain real-time insights into their processes. This predictive technology helps optimize production efficiency and minimize downtime, leading to greater cost savings and improved output. Furthermore, as the demand for sustainable practices grows, researchers are exploring eco-friendly methods for tungsten extraction and processing, ensuring that polished tungsten plates contribute to a greener manufacturing landscape.

Home

About Us

Products

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us

Polished tungsten plates stand out due to their remarkable properties, such as high density, excellent thermal conductivity, and superior resistance to wear and corrosion. These attributes make them ideal for applications ranging from high-temperature environments to precision components in cutting-edge technological innovations.

As manufacturers seek to optimize performance and enhance product longevity, understanding the benefits and applications of polished tungsten plates becomes increasingly vital for maintaining competitive advantages in the marketplace.

Polished tungsten plates stand out due to their remarkable properties, such as high density, excellent thermal conductivity, and superior resistance to wear and corrosion. These attributes make them ideal for applications ranging from high-temperature environments to precision components in cutting-edge technological innovations.

As manufacturers seek to optimize performance and enhance product longevity, understanding the benefits and applications of polished tungsten plates becomes increasingly vital for maintaining competitive advantages in the marketplace.

Polished tungsten plates have steadily gained recognition in modern manufacturing, primarily due to their unique properties and advantages. These plates are renowned for their exceptional hardness and high melting point (

Polished tungsten plates have steadily gained recognition in modern manufacturing, primarily due to their unique properties and advantages. These plates are renowned for their exceptional hardness and high melting point (