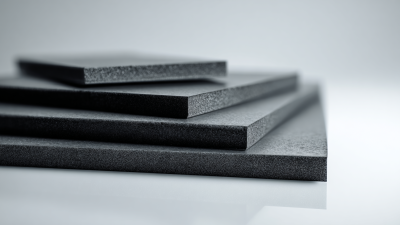

Why Choose Blank Carbide Plates for Your Manufacturing Needs?

In the world of manufacturing, the selection of materials plays a crucial role. Experts are turning their attention to Blank Carbide Plates. John Smith, a renowned industry expert, once stated, "The durability of Blank Carbide Plates can significantly enhance production quality." His insight reflects a growing trend among manufacturers seeking reliability.

Blank Carbide Plates offer unique advantages. They are known for their hardness and resistance to wear. This durability translates into longer tool life and less frequent replacements. Many manufacturers find that investing in these plates saves both time and money. However, the initial cost can be challenging for some businesses.

Despite their benefits, there are considerations. Not every application requires the strength of Blank Carbide Plates. Some industries may not need such robust material. Evaluating specific manufacturing needs is critical for decision-making. It's important to weigh the pros and cons before choosing the right material. As the industry evolves, so too must our understanding of material applications.

Benefits of Using Blank Carbide Plates in Manufacturing

Blank carbide plates have become essential in the manufacturing sector. Their unique properties make them highly effective for various applications. According to a report by the International Journal of Advanced Manufacturing Technology, using carbide plates can enhance tool longevity by up to 50%. This is a significant improvement that manufacturers cannot overlook.

The benefits of carbide plates extend beyond durability. They offer excellent wear resistance and thermal stability. In high-pressure environments, these plates maintain their integrity. The average tool life increases by approximately 30% when using quality carbide products. However, not all manufacturers choose to invest in this technology. Some opt for cheaper alternatives, risking performance and longevity. It’s worth considering whether short-term savings are worth the potential long-term costs.

Another consideration involves the availability of carbide plates. Sourcing high-quality materials can be challenging. Some manufacturers find themselves with inconsistent supply chains. This leads to production delays and increased operational costs. Investing in reliable suppliers for blank carbide plates can streamline processes. It enhances efficiency, ultimately benefiting the bottom line. Embracing innovation in material selection can result in substantial rewards over time.

Understanding the Properties of Carbide Plates

Carbide plates have become essential in many manufacturing processes due to their unique properties. These plates are known for their high hardness, which makes them resistant to wear and tear. Reports show that carbide materials can withstand temperatures exceeding 1000°C while maintaining structural integrity. This stability is crucial in high-pressure environments, where other materials might fail.

When selecting carbide plates, consider product longevity and cost-effectiveness. Companies often see a reduction in downtime by 30% when using high-quality carbide materials. However, not all carbide plates are the same. Quality varies, affecting performance and lifespan. It's important to evaluate the specific application needs before purchasing.

Tip: Always check the material specifications and hardness rating. Higher hardness usually correlates with better performance.

The production of carbide plates involves precise techniques. Variations in manufacturing can lead to inconsistencies. A poor-quality plate can diminish operational efficiency, leading to increased costs and potential safety risks. Understanding the nuances in the properties of carbide plates is crucial for making informed decisions.

Tip: Don't rush your decision-making process. Research thoroughly to avoid future regrets.

Properties of Carbide Plates Compared to Other Materials

This chart illustrates the superior properties of carbide plates compared to steel and aluminum plates, highlighting their higher tensile strength, hardness, wear resistance, and temperature resistance, making them ideal for various manufacturing applications.

Comparative Analysis: Carbide Plates vs. Other Materials

When comparing carbide plates to other materials, their durability stands out. Carbide plates are often harder than steel, making them resistant to wear and tear. A recent industry report indicates that carbide can offer a 20% longer lifespan compared to steel plates under similar conditions. This makes them highly effective for demanding manufacturing applications.

On the flip side, carbide plates can be more brittle. They may not withstand sudden impacts as well as some other materials. This fragility must be considered during the selection process. For some applications, a tougher but less hard material might be beneficial. Understanding the balance between hardness and toughness is essential in manufacturing.

Tips: Evaluate your specific use case carefully. Consider the material's impact resistance alongside its wear resistance. Sometimes, mixing materials may provide the perfect solution to your manufacturing challenges. Always revisit your choices as technology evolves. Keep an eye on recent findings, as industry standards change frequently.

Applications of Blank Carbide Plates in Various Industries

Blank carbide plates are gaining popularity in various industries due to their durability and versatility. In manufacturing, they serve as essential components in machining and cutting tools. Their hardness allows them to withstand high wear and tear. This quality is beneficial in automotive and aerospace sectors, where precision is crucial.

In the oil and gas industry, blank carbide plates are used for drilling equipment. Their strength helps reduce downtime, but mistakes can occur during installation. It's vital to ensure proper alignment to avoid premature wear. In electronics, these plates are utilized in the production of circuit boards. This requires meticulous attention to detail to achieve optimal performance.

Despite their advantages, one must consider the costs involved. Investment in carbide plates can be significant. Some may find cheaper alternatives tempting, yet these often lead to increased long-term expenses. Reflecting on the balance between cost and durability is essential for informed decision-making.

Factors to Consider When Selecting Carbide Plates for Your Needs

When considering carbide plates for manufacturing, several key factors emerge. Material hardness is vital. Blank carbide plates offer excellent wear resistance. This property significantly prolongs the service life of tools. Manufacturers often overlook this aspect, focusing instead on price alone. Until they experience wear, that is.

Next, thickness plays a crucial role. Thicker plates can withstand greater stress and heat. However, they are also heavier and may complicate machining processes. Balancing weight and durability is not always straightforward. It's essential to evaluate how thickness impacts your specific applications.

Surface finish cannot be ignored. A smooth finish promotes better performance in many applications. Rough surfaces can lead to friction and reduce efficiency. Some users underestimate how this affects overall production. Evaluating these factors carefully leads to better decision-making. Take time to analyze your unique requirements before purchasing.

Why Choose Blank Carbide Plates for Your Manufacturing Needs?

| Factor |

Description |

Benefits |

| Material Composition |

Blank carbide is made from a tungsten carbide matrix with a cobalt binder, providing exceptional hardness. |

High wear resistance and durability, effective in machining and tooling applications. |

| Manufacturing Precision |

Allows for tight tolerances and accurate dimensions during the fabrication process. |

Enhances product quality and reduces waste in manufacturing processes. |

| Thermal Conductivity |

Effective heat dissipation allows carbide plates to maintain their integrity under high temperatures. |

Reduces risk of thermal deformation during machining, enhancing operational efficiency. |

| Versatility |

Can be used in various applications, including cutting tools, dies, and wear parts. |

Flexible solutions for multiple industries, reducing the need for different material types. |

| Cost-effectiveness |

Long lifespan and reduced maintenance costs compared to traditional materials. |

Lower overall operational costs due to extended life and reduced downtime. |

Home

About Us

Products

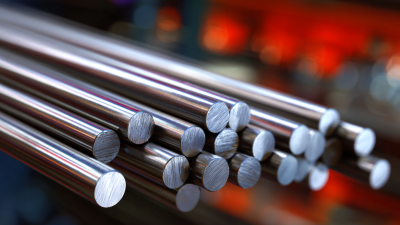

Solid Carbide Rods

Carbide Rods with coolant holes

Carbide Rods with Two Helix Holes

Tungsten Carbide Flats

Solid Carbide Discs

Tungsten Carbide anti-vibration cylindrical shafts

Non-standard Customized Carbide Blanks

Solid Carbide Circular Saw Blade

Solid Carbide Woodworking Blade

Solide Carbide End Mills

Solid Carbide Drills

Carbide Rotary Burrs

Customized Carbide Tools

News

FAQS

Contact Us