Factory Price For Hrc55 End Mill - Solid Carbide Custom Reamers as drawing – CEMENTED CARBIDE

Factory Price For Hrc55 End Mill - Solid Carbide Custom Reamers as drawing – CEMENTED CARBIDE Detail:

1. High hardness

2. High abrasion and corrosion resistance.

3. High pressure resistance

4. High temperature resistance

5. Products with advanced equipment and perfect workmanship

Sizes Range:D1.0~20.0mm,L:50~200mm

Detailed sizes could be made as per customers’ requirement or drawings.

1.We have more than 50 years production and management experience and have complete industrial chain from tungsten powder to precision milling tools.

2.We has obvious technology advangages,we always maintained the advanced position in technological R&D capability in China,and has owned a provincial-level technology center,as well as an analysis and test center,with 112 personnel holding senior professional and technical titles,master’s degree or above.Meanwhile,we have set up a professional laboratory to test the properties and parameters for tungsten carbide powder and tungsten carbide alloys.

3.We have stable and reliable manufacturing system,which with advanced process equipments like ROLLOMATIC processing machine,Walter machine;DJ machine; talented professionals and perfect quality assurance system.

4.Perfect quality assurance system.

We strictly implements the ISO9001:2015 qualitymanagement system,and implements the whole staff quality responsibility system to ensure continuous and efficient service to clients.

5.Super 100% original raw material

Normally,we use NCC Rods(our own rods) or GESAC Rods(China Mainland)

Also,imported rods like Sandvik rods could be used according to your requirement.

6.Super Coating

TiSiN Nano coating

7.Advanced Equipment

Rollomatic for small end mills

Walter for non-standard end mills

DJ machine for standard end mills

8.Wide Application

HRC50 suitable for common Steel,Cast Iron;

HRC55 suitable for unhardened stainless steel;

HRC60 suitable for pre-hardened steel;

HRC65 suitable for hardened steel,finish machining.

9.Custom Logo Could be Printed on products.

Custom box and Label could be used as per Customer’s requirement.

10. Short Delivery Time

Normally,our delivery time is in 5-20 days,5-7days for small order and 15-20 days for large quantity order.

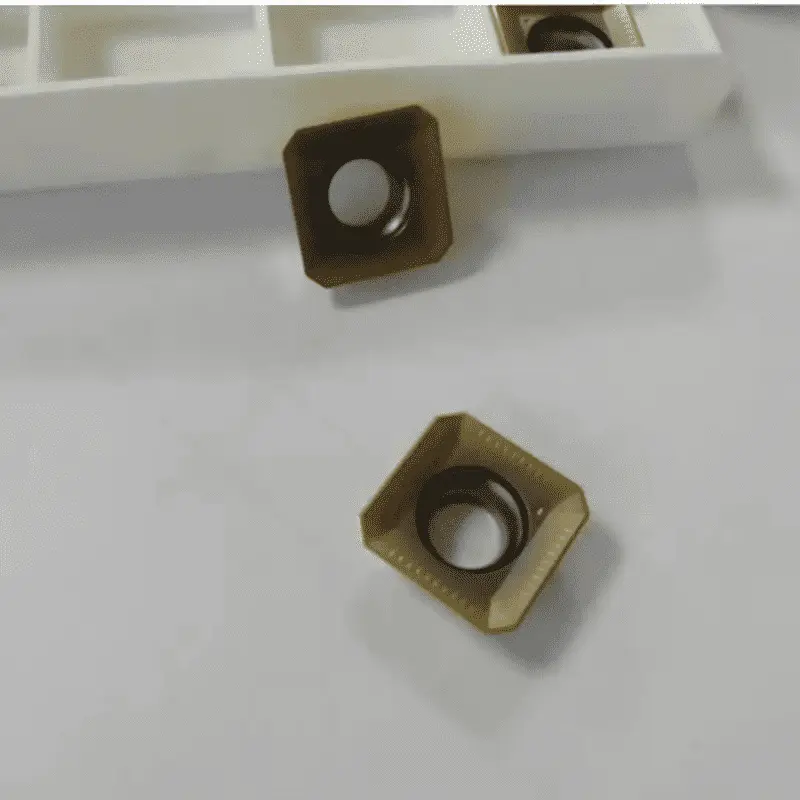

Product detail pictures:

Related Product Guide:

The customer satisfaction is our primary target. We uphold a consistent level of professionalism, quality, credibility and service for Factory Price For Hrc55 End Mill - Solid Carbide Custom Reamers as drawing – CEMENTED CARBIDE , The product will supply to all over the world, such as: Amsterdam, Canada, Nepal, With excellent solutions, high quality service and sincere attitude of service, we ensure customer satisfaction and help customers create value for mutual benefit and create a win-win situation. Welcome customers all over the world to contact us or visit our company. We'll satisfy you with our qualified service!

By Riva from Germany - 2018.09.21 11:44

By Riva from Germany - 2018.09.21 11:44

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.

By Helen from Manchester - 2017.02.14 13:19

By Helen from Manchester - 2017.02.14 13:19