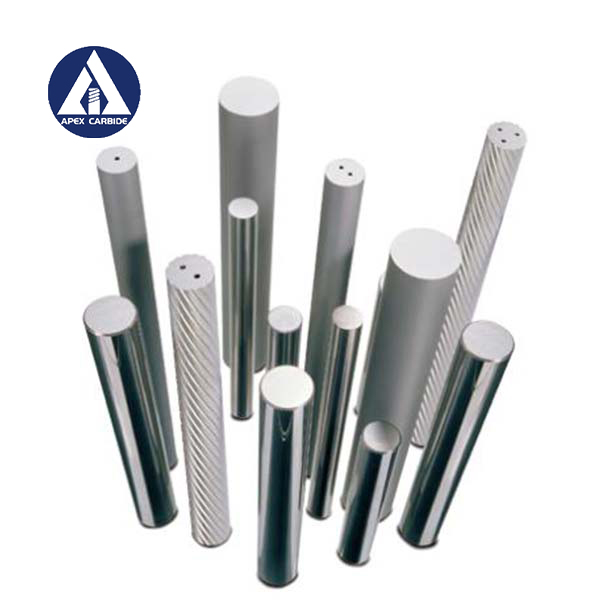

Top Supplier of Wholesale Nano Blue Coating Mills - Premium Manufacturing Solutions

As a leading supplier of advanced Nano Blue Coating Mills, Jiangxi Apex Carbide Co., Ltd. is dedicated to delivering high-quality products tailored to the demands of diverse industries. Our mills incorporate state-of-the-art technology, ensuring exceptional performance and durability for all applications. Operating from China, we understand the requirements of B2B purchasers and provide effective solutions to enhance your manufacturing processes. Designed with a focus on precision and efficiency, our nano blue coating mills are suitable for a variety of materials. Collaborating with us guarantees reliable equipment sourced from reputable factories, backed by our commitment to customer satisfaction and seamless support throughout the purchasing journey. Experience superior performance and quality with us as we work towards a successful partnership.Must-Know Tips For Nano blue coating mills Delivers Unmatched Quality Dominates

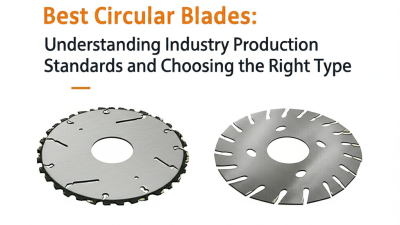

When it comes to sourcing high-quality cemented carbide products, understanding the advantages of nano blue coating is a game-changer. Jiangxi Apex Carbide Co., Ltd. specializes in providing premium cemented carbide solutions, including carbide rods, plates, blades, and circles. Our advanced nano blue coating technology not only enhances the performance of our products but also ensures unparalleled quality that sets us apart in the global market. Nano blue coating offers significant benefits, such as improved wear resistance and reduced friction, making our Carbide Tools and components ideal for precision engineering and manufacturing applications. With an annual output of 2000 tons of carbide blanks, we ensure that our clients receive durable, high-performance products that meet their exact specifications. By choosing Jiangxi Apex Carbide, global buyers can rest assured they are investing in tools that provide longer life cycles and maintain their efficiency under demanding operational conditions. In today's competitive landscape, procurement strategies must focus on quality and reliability. By collaborating with a trusted manufacturer like Jiangxi Apex Carbide, procurement professionals can gain a competitive edge. Our commitment to excellence, backed by rigorous quality control throughout the production process, guarantees that our nano blue coated products will dominate the market, delivering unmatched performance for your business needs. Explore the difference with Jiangxi Apex Carbide and elevate your manufacturing capabilities.

Must-Know Tips For Nano Blue Coating Mills Delivers Unmatched Quality Dominates

| Parameter | Description | Value |

|---|---|---|

| Coating Thickness | Standard thickness range for optimal performance | 5-15 µm |

| Durability Test | Resistance to wear and tear | 1000 Cycles |

| Heat Resistance | Maximum temperature before coating failure | 400 °C |

| UV Resistance | Ability to withstand UV exposure without degradation | 1000 Hours |

| Surface Hardness | Measurement of hardness post-coating | HV 2000 |

| Process Efficiency | Time taken for coating application | 30 Minutes |

Why Trust Nano blue coating mills Is The Best Supplier

N

Natalie H. Adams

The level of expertise from the staff was apparent and made all the difference in my purchasing experience.

22 June 2025

H

Henry W. Young

Both the product and service were exemplary! Each interaction left me feeling well taken care of.

12 June 2025

E

Emma N. Garcia

Very pleased with the craftsmanship of the product! Service provided was equally exceptional.

08 June 2025

S

Sofia B. Wright

Absolutely satisfied with this purchase. The quality is unmatched, and the staff were exceptionally helpful!

10 May 2025

O

Oliver J. Martinez

Great quality product! The service team treated my inquiries with utmost care and professionalism.

10 June 2025

S

Sophie M. Rogers

Stellar product! The professionalism shown by the support staff was greatly appreciated.

16 June 2025