OEM/ODM Factory Nanchang Hard Alloy - Tungsten Solid Carbide Rods for End Mills and Drills with stable high quality – CEMENTED CARBIDE

OEM/ODM Factory Nanchang Hard Alloy - Tungsten Solid Carbide Rods for End Mills and Drills with stable high quality – CEMENTED CARBIDE Detail:

1.The tungsten solid carbide rods is press molded by molding or extrusion.

2.The tungsten solid carbide rods is sintered by a low-pressure sintering integrated furnace, thus the overall performance is high.

3.The rough tungsten-cobalt carbide round bar, or the outer diameter of the round bar can be refined and polished according to any tolerance. The common tolerances are h5,h6, -0.005, etc., and the carbide rods end chamfer can also be processed.

4.Carbide rods is suitable for the processing of general steel, cast iron, stainless steel, heat resistant steel, nickel base and titanium alloy. Recommended for general purpose carbide tool materials such as twist drills, end mills, taps, and gun drills.

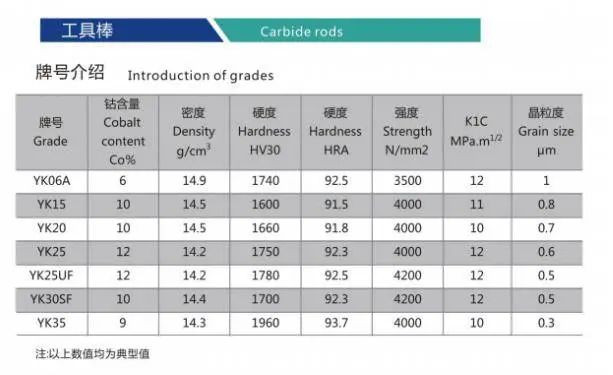

Our Tyopes of carbide Rods

1.Unground Long rods

| The TOL. of Unground Long rods | ||

| Size(DxL,mm) | Tolerance | |

| D(mm) | L(mm) | |

| D[1-3)x310/330 | 0.30~0.55 | 0.00~+4.00 |

| D[3-12)x310/330 | 0.30~0.60 | 0.00~+4.00 |

| D[12-20)x310/330 | 0.30~0.65 | 0.00~+4.00 |

| D[20-40]x310/330 | 0.30~0.70 | 0.00~+4.00 |

2.Unground cut-to-length rods

| The TOL. of unground cut-to-length rods | ||

| D/L(mm) | The TOL.of D&L in mm | |

| L<=70 | 70<L<=150 | |

| D<5 | D(0.20~0.30), L(0.20~1.5) | D(0.25~0.35), L(0.20~1.5) |

| 5<=D<40 | D(0.25~0.35), L(0.20~1.5) | D(0.30~0.40), L(0.20~1.5) |

3.Ground long rods

The tolerance of the long rods is h5/h6 or at customer’s requirement in Dia. ,and 0.00~+5.00mm in Length as normal.

4.Ground cut-to-length rods

The tolerance of the ground cut-to-length rods is h5/h6 or at customer’s requirement in Dia. ,and 0.00~+2.00mm in Length as normal.

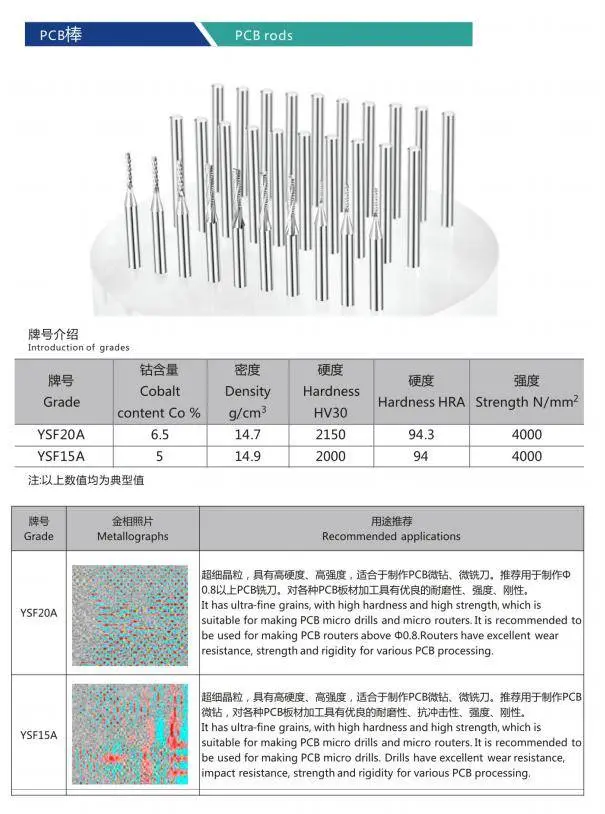

5.PCB Rods

more than 50 years production and management experience,Advanced production technology, High-precision machines, Strict QC management system, Special-designed packing boxes and tubes, Various shipping methods

1.Tungsten carbide blanks production

2.Inspection and testing process

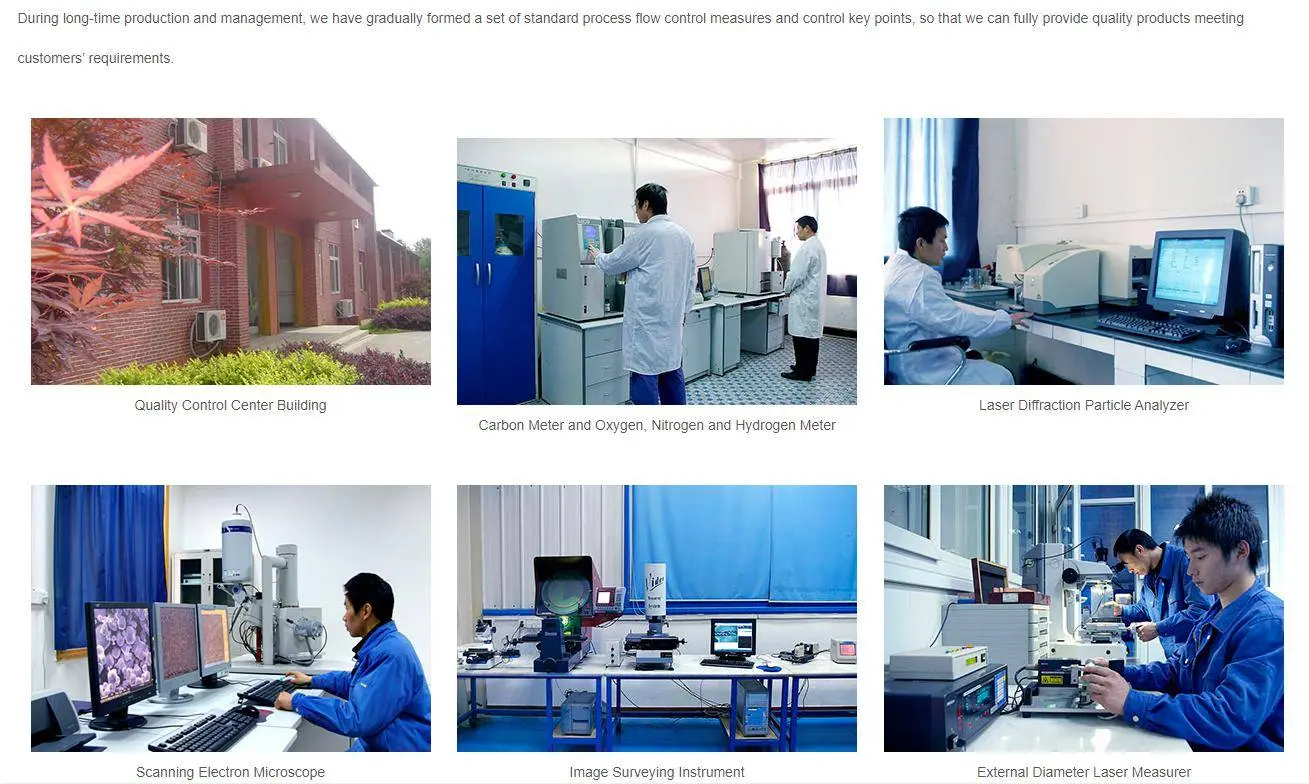

In order to ensure the quality of all our tungsten carbide finished products, a very strict QC management system we called “Quality Control Center” has been introduced. With our advanced inspection equipment and our professional inspectors, we are able to do raw materials inspection, on-site inspection and after finishing inspection to ensure 100% good quality of your carbide products.

3.Advanced CNC Equipment

NCC owns a series of high-precision grind machines, including flat grinding machines, OD and ID machines, Centerless grinding machines and customized grinders. Also we have CNC machines, EDM, Wire-cutting machines and drilling machines etc. With our skilled workers, we can control very high precision of each carbide part.

4.Packaging and Shipping

Special-designed packing boxes and tubes will be used properly for the standard and customized carbide products to ensure the safety of the goods during the transportation process.A wide range of shipping ways can be available for your shipments, for example we can ship goods by Sea, by air and by Express companies like DHL/FedEx/UPS/TNT etc.

Product detail pictures:

Related Product Guide:

With advanced technologies and facilities, strict quality control, reasonable price, superior service and close co-operation with customers, we are devoted to providing the best value for our customers for OEM/ODM Factory Nanchang Hard Alloy - Tungsten Solid Carbide Rods for End Mills and Drills with stable high quality – CEMENTED CARBIDE , The product will supply to all over the world, such as: Sao Paulo, Grenada, California, We hope to have long-term cooperation relationships with our clients. If you are interested in any of our products, make sure you do not hesitate to send enquiry to us/company name. We ensure that you can be totally satisfied with our best solutions!

By Kimberley from Montreal - 2018.09.23 18:44

By Kimberley from Montreal - 2018.09.23 18:44

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!

By Christine from Gabon - 2017.07.28 15:46

By Christine from Gabon - 2017.07.28 15:46