Wholesale Solid End Mills from Reliable Factories and Trusted Suppliers Online

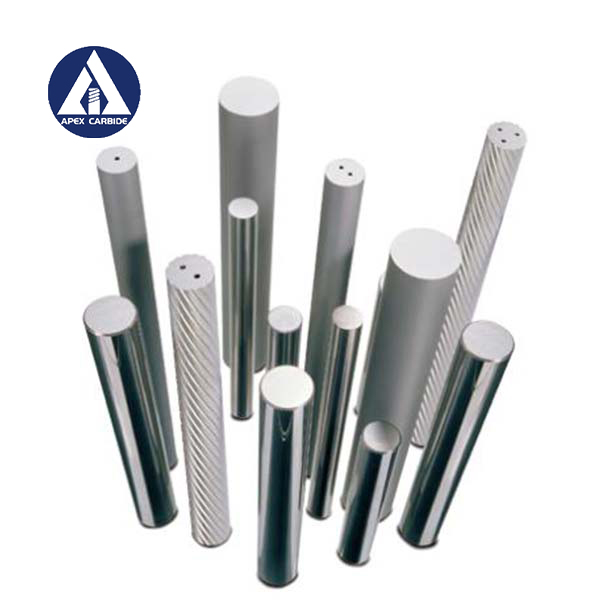

When it comes to high-performance cutting tools, solid end mills are essential for precision machining. They ensure reliability in production processes, making it crucial to find quality manufacturers and suppliers that offer competitive wholesale pricing. Jiangxi Apex Carbide Co., Ltd. excels in the market with a comprehensive range of solid end mills designed for durability and cutting efficiency. Their products are tailored to meet the demanding needs of various industries, guaranteeing optimal performance and minimal downtime. By choosing a trusted partner like Jiangxi Apex Carbide Co., Ltd., you can enhance your machining capabilities while keeping costs down. Prioritize quality with solid end mills crafted to withstand the test of time and meet your specific requirements.Cutting-Edge solid end mills Custom Solutions, Ahead of the Curve

In an ever-evolving manufacturing landscape, the demand for precision tools is at an all-time high. Cutting-edge solid end mills are essential for delivering superior performance in various applications, from aerospace to automotive industries. These advanced tools are designed to provide exceptional wear resistance, improved chip removal, and enhanced cutting efficiency. By investing in custom solutions, manufacturers stand to gain a significant competitive edge, maximizing productivity while minimizing downtime. Our commitment to innovation and quality ensures that we offer a wide range of solid end mill designs tailored to meet the specific needs of our global clients. With an annual output of 2000 tons of carbide blanks, we understand the importance of reliable, high-performance tools. We work closely with our partners to develop bespoke end mills that not only meet industry standards but also exceed expectations. By staying ahead of the curve, we enable businesses to streamline their operations and achieve remarkable results. In an era where precision and efficiency are paramount, adopting advanced solid end mill solutions is no longer just an option—it’s a necessity. By choosing cutting-edge products that are crafted with the latest technology, businesses can tackle complex projects with confidence, drive innovation, and ultimately secure their position as leaders in their respective markets. Embracing custom solutions in tooling not only enhances operational efficiency but also fosters long-term sustainable growth in an increasingly competitive global environment.

Cutting-Edge Solid End Mills Custom Solutions, Ahead of the Curve

| Model | Diameter (mm) | Coating Type | Material | Flute Count | Application |

|---|---|---|---|---|---|

| EEM-01 | 6 | TiN | HSS-E | 4 | General Machining |

| EEM-02 | 8 | TiAlN | Carbide | 3 | Aluminum Machining |

| EEM-03 | 10 | ZrN | HSS | 5 | Stainless Steel |

| EEM-04 | 12 | AlTiN | Carbide | 6 | Titanium Alloys |

| EEM-05 | 16 | Diamond Coated | Solid Carbide | 8 | Composites |

Curated Selection of solid end mills Exceeds Industry Benchmarks Pioneers in the Field

S

Sophia W. Taylor

The professionals who assisted me were not only friendly but also very knowledgeable, putting my mind at ease.

20 June 2025

O

Oliver T. Scott

This product delivers exceptional performance. I also appreciate the prompt customer service that was provided.

29 May 2025

J

Jennifer K. Rivera

This purchase was worth every penny! The professionalism displayed by the support team was impressive.

25 May 2025

G

Gavin Y. Martinez

The craftsmanship of the product was much appreciated! Excellent service too!

06 July 2025

M

Maria K. Bennett

Fabulous product quality! Timely and professional support made it even better.

22 June 2025

A

Ava K. Morgan

This product is phenomenal! The service was equally commendable and professional.

15 May 2025