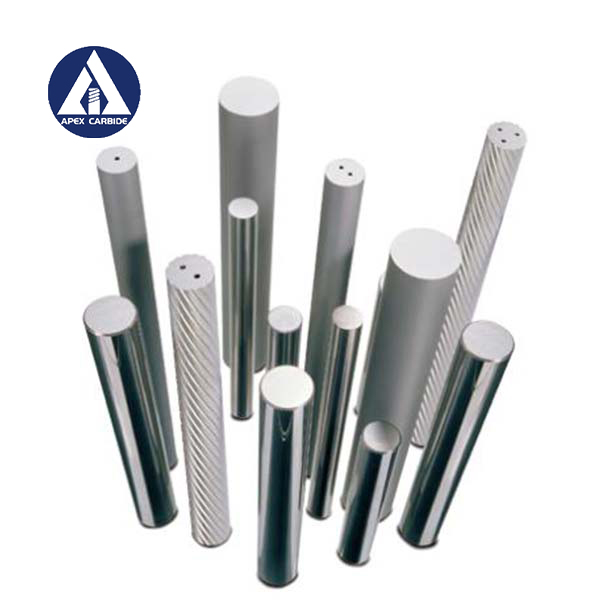

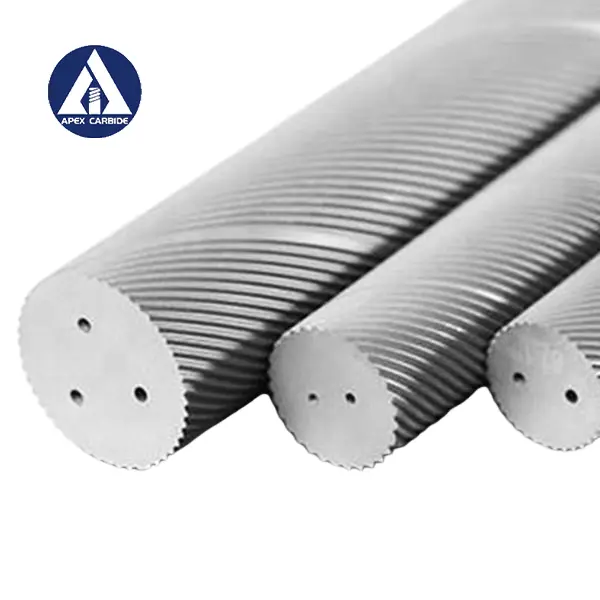

Tungsten Alloy Rods: High-Quality Solutions for Diverse Industrial Applications

Tungsten Alloy Rods stand out for their exceptional density and durability, making them ideal for applications requiring superior strength and heat resistance. Whether utilized in aerospace, medical, or defense sectors, these rods excel in the most demanding environments. For further information or to discuss specific applications, feel free to reach out. Let’s collaborate to meet your tungsten alloy needs!

Methods To Choose Tungsten Alloy Rods Products Factory

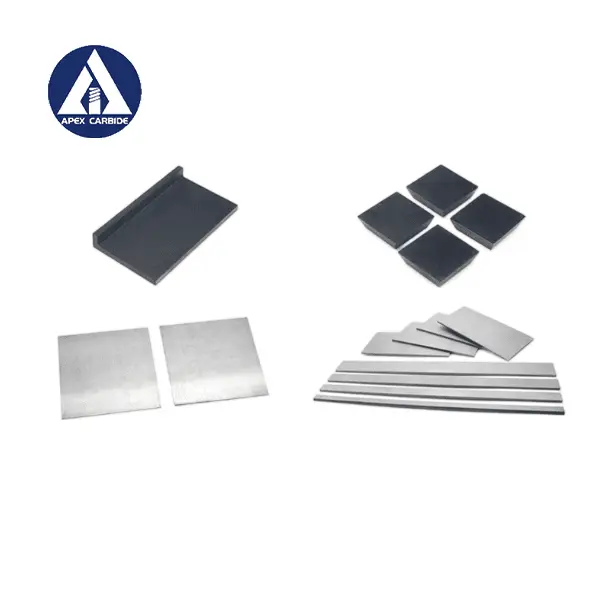

When selecting a tungsten alloy rods products factory, there are several key factors that global buyers should consider to ensure they partner with a reliable manufacturer. First and foremost, it’s essential to assess the factory’s expertise in producing high-quality cemented carbide products, such as those provided by Jiangxi Apex Carbide Co., Ltd. With an impressive annual output of 2000 tons of Carbide Blanks, this company has established a solid reputation for excellence within the industry. Another critical factor is the range of products offered. Buyers should look for a factory that not only specializes in tungsten alloy rods but also provides diverse options like carbide plates and blades. This versatility often indicates a well-rounded manufacturing capability and the ability to meet various application needs. Additionally, checking for certifications and quality control measures can assure buyers of the factory's commitment to maintaining high standards in production. Finally, communication and customer support are vital when choosing a factory. A manufacturer that prioritizes clear communication and offers responsive service can significantly enhance the purchasing experience. Jiangxi Apex Carbide Co., Ltd is dedicated to building strong relationships with clients worldwide, ensuring that purchasing high-quality tungsten alloy rods becomes a seamless process. By keeping these considerations in mind, global buyers can make informed decisions when selecting their manufacturing partner.

Methods To Choose Tungsten Alloy Rods Products Factory

| Criteria | Description | Importance Level | Example Value |

|---|---|---|---|

| Material Composition | Percentage of tungsten, nickel, iron, etc. | High | Tungsten 90%, Nickel 7%, Iron 3% |

| Density | Weight per unit volume, affects performance. | High | 18.5 g/cm³ |

| Production Process | Method used to manufacture the rods. | Medium | Powder metallurgy |

| Quality Certifications | Industry certifications for quality assurance. | High | ISO 9001, RoHS |

| Tolerance Levels | Precision in dimensions during production. | High | ±0.02 mm |

| Lead Time | Time required to produce and deliver products. | Medium | 4-6 weeks |

| Pricing | Cost per unit or pricing structure options. | High | $150 - $250 per kg |

Best Way To Choose Tungsten Alloy Rods Manufacturer Factory

L

Liam B. Davis

Very pleased with the product quality! The service staff were incredibly helpful and professional.

27 June 2025

C

Charlotte M. Lee

The product simply outperforms my expectations, and the service team was always there when I needed them.

21 May 2025

M

Mason J. Sanchez

This item has exceeded my expectations. The after-sales support is second to none.

16 May 2025

J

Jackson T. Green

Exactly what I was informed it would be! Great product and reliable service.

06 July 2025

M

Maria J. Fisher

Absolutely pleased! The quality is amazing and the service was professionally handled.

26 June 2025

E

Ella G. Morgan

A delightful experience all around! Quality product backed by dedicated service.

15 May 2025