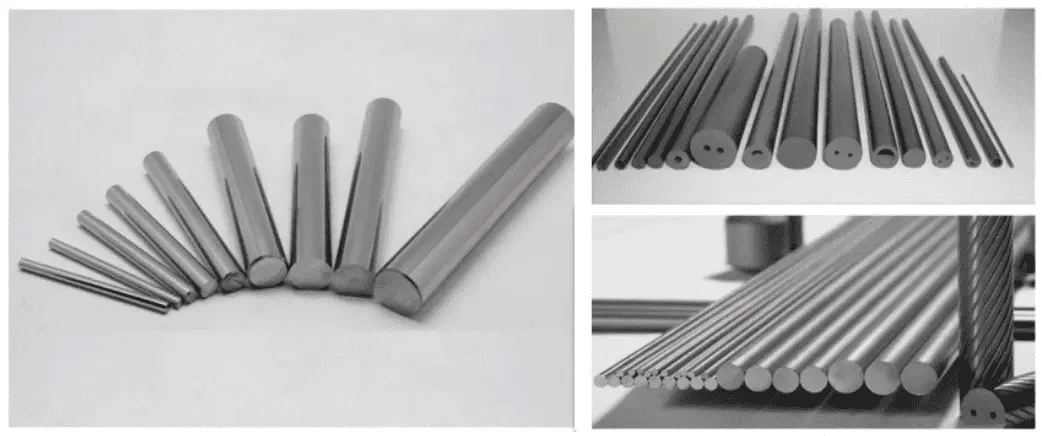

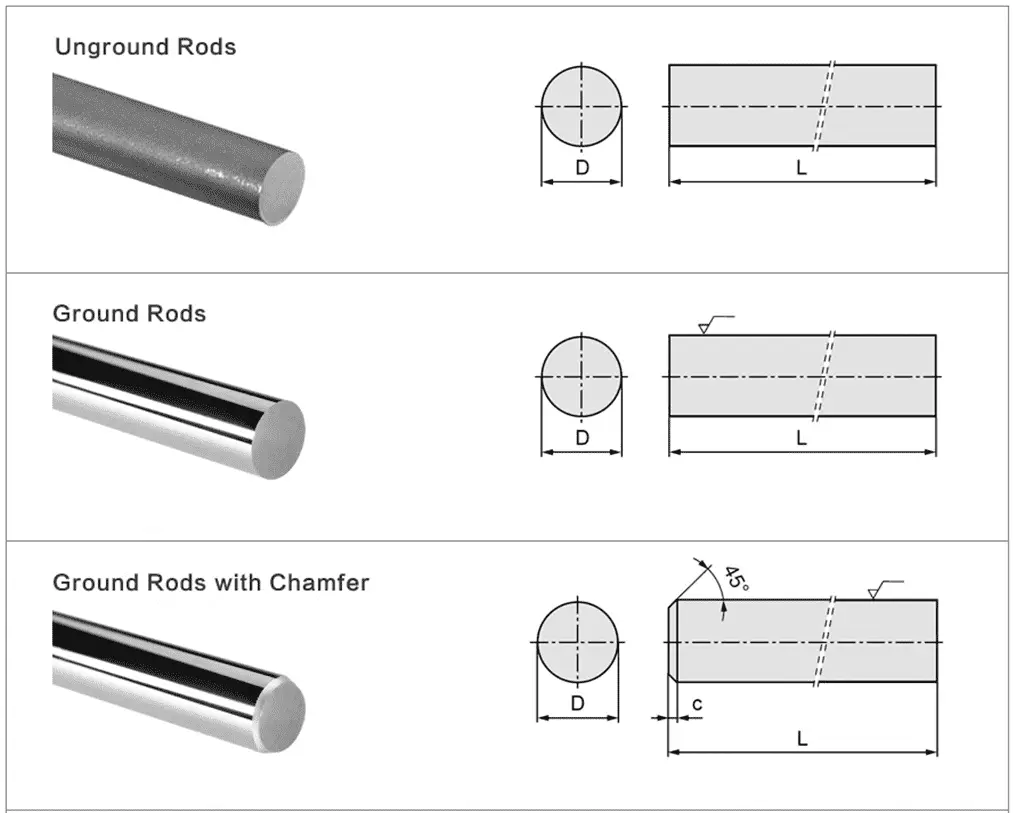

- Solid Carbide Rods

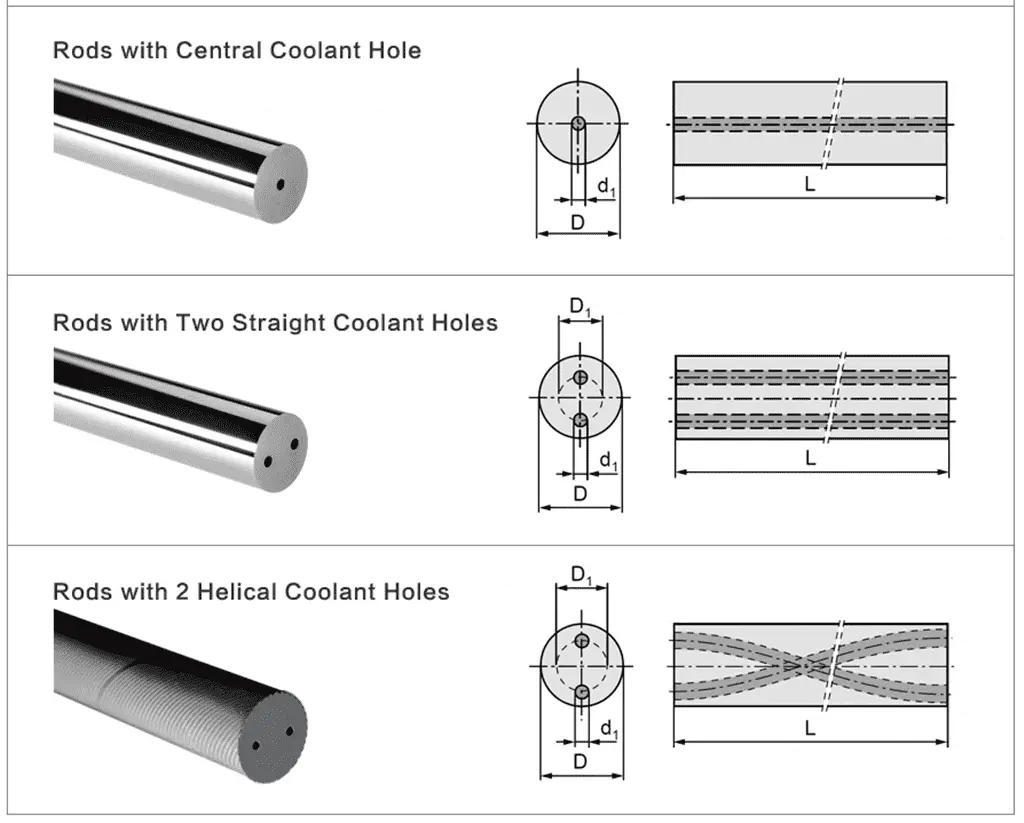

- Carbide Rods with coolant holes

- Carbide Rods with Two Helix Holes

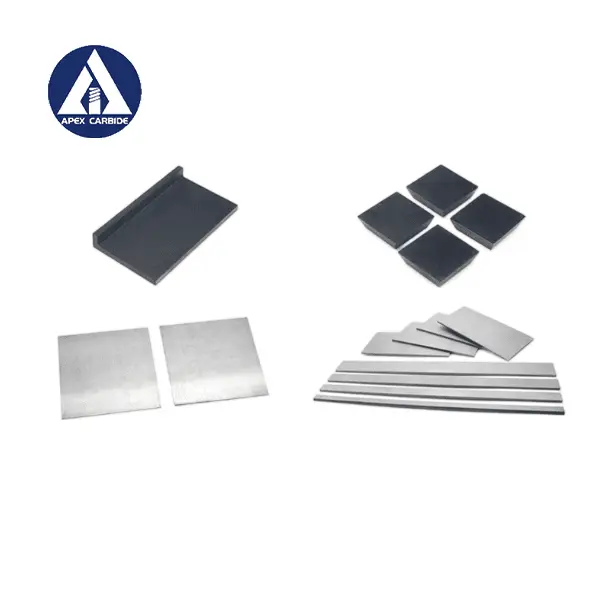

- Tungsten Carbide Flats

- Solid Carbide Discs

- Tungsten Carbide anti-vibration cylindrical shafts

- Non-standard Customized Carbide Blanks

- Solid Carbide Circular Saw Blade

- Solid Carbide Woodworking Blade

- Solide Carbide End Mills

- Solid Carbide Drills

- Carbide Rotary Burrs

- Customized Carbide Tools

0102030405

Tungsten Carbide Rods with two helix coolant holes and 30 or 40 degree blank or h5 ground

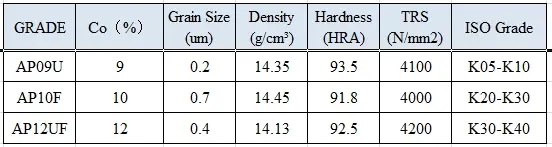

Our Main Grades Introduction

Other grades could be introducted and made as per your application.

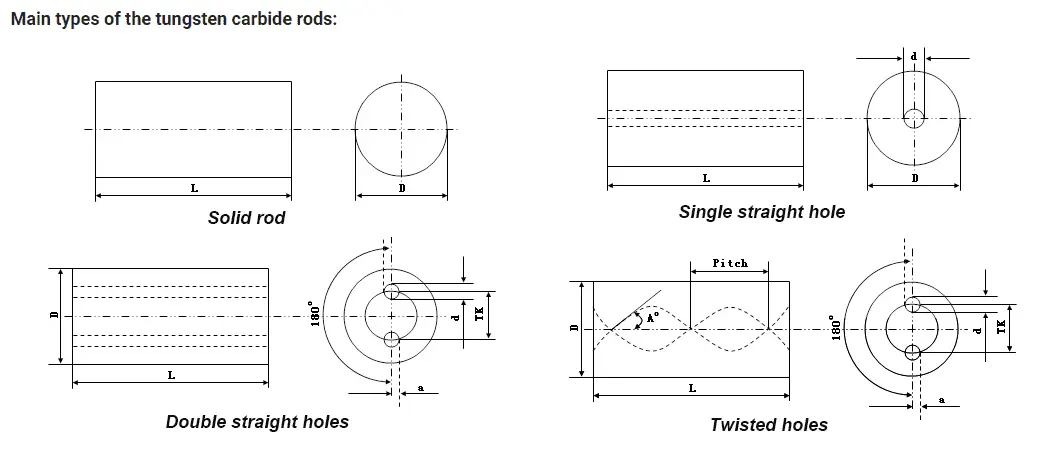

Main types of Tungsten Carbide Rods

Our Types of carbide Rods

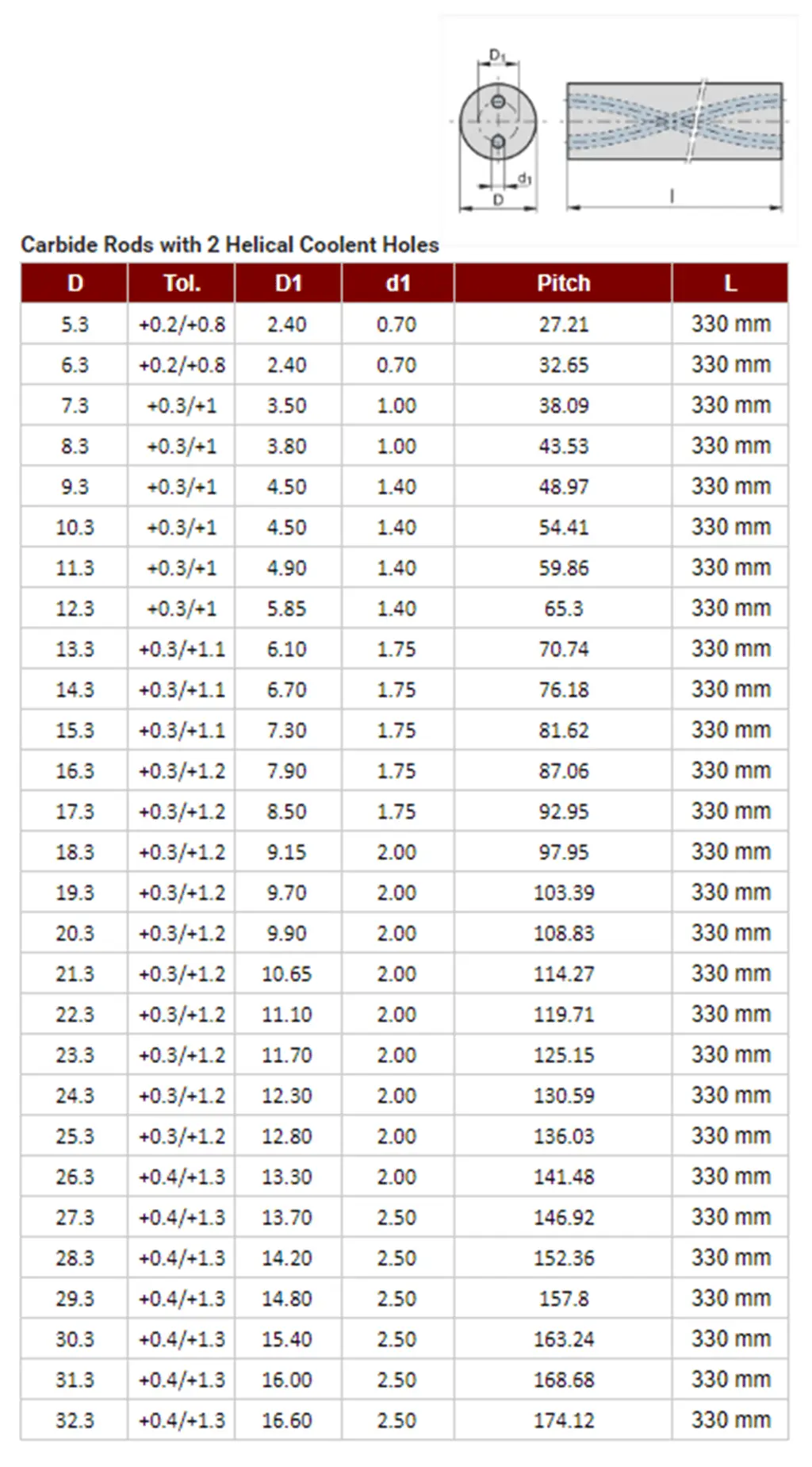

Our Standard Sizes of rods with two helical holes

Main Application:

1.For making tungsten carbide dental burrs.

2.For making tungsten carbide PCB drills,drills,end mills,hole drilling tools.

3.For making tungsten carbide reamers.

4.For making tungsten carbide mold punches

5.For making tungsten carbide core pins

Production Process

Why Choose APEX Carbide

Around 20 years production and management experience,Advanced production technology, High-precision machines, Strict QC management system, Special-designed packing boxes and tubes, Various shipping methods

2.Inspection and testing process

3.Advanced CNC Equipment

1.Tungsten carbide blanks production

Good quality carbide products rely on 100% virgin raw materials and advanced wet-milling,pressing machines and sintering furnaces. We put emphasize on every production process of our carbide blanks. To keep good quality of carbide blanks is the base of furtherly machined high precision finished carbide parts.

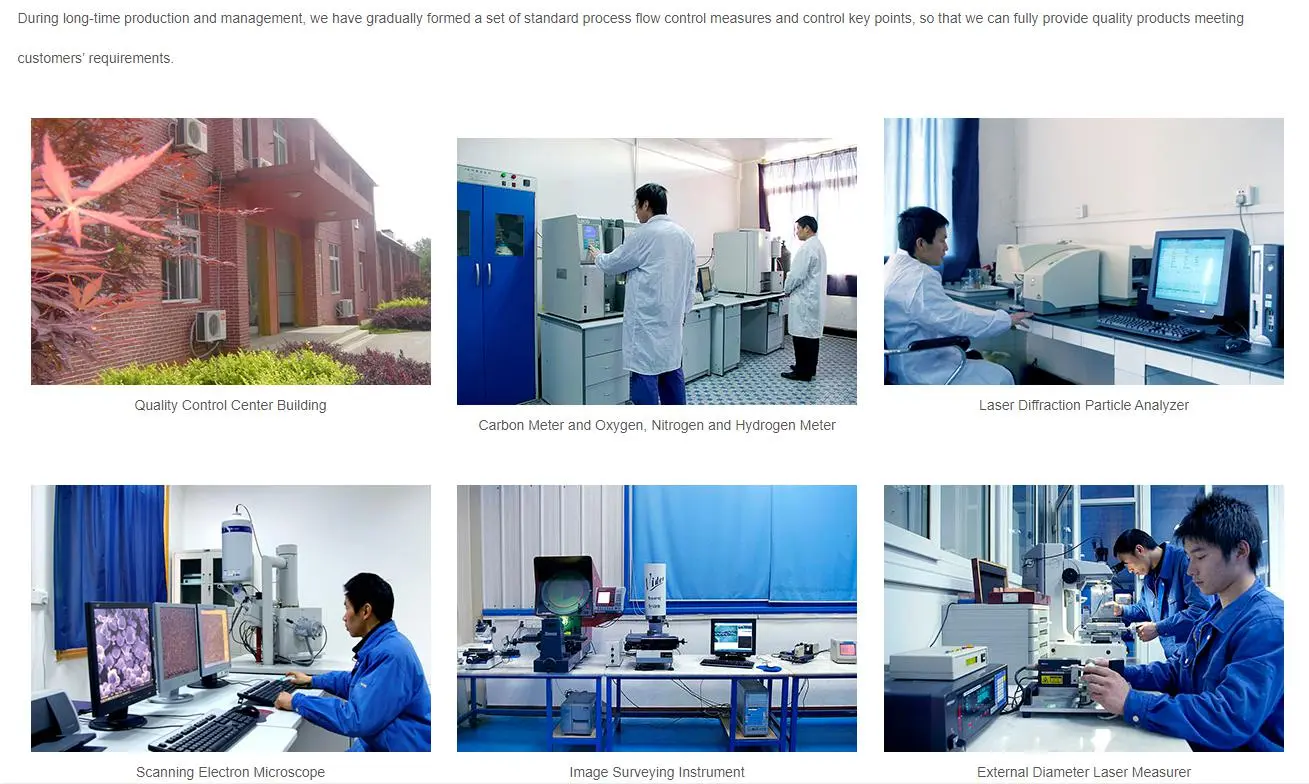

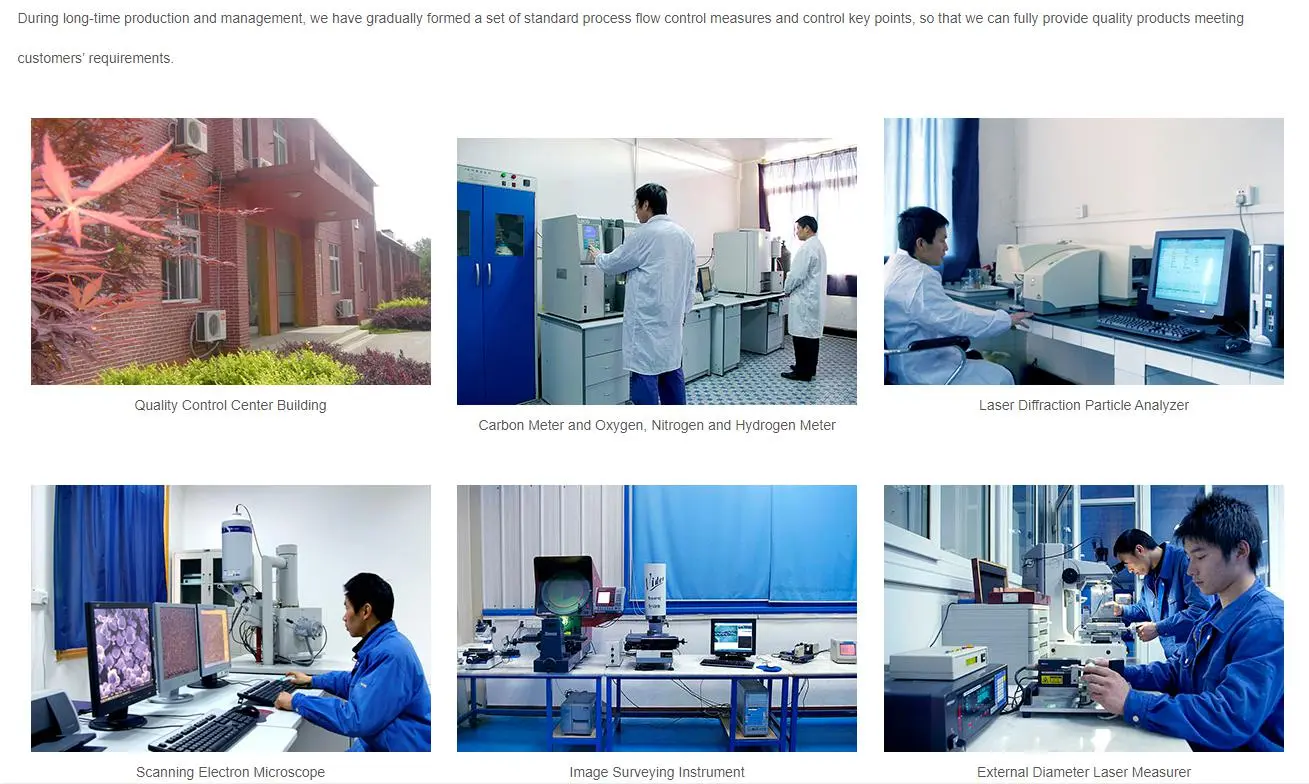

2.Inspection and testing process

In order to ensure the quality of all our tungsten carbide finished products, a very strict QC management system we called “Quality Control Center” has been introduced. With our advanced inspection equipment and our professional inspectors, we are able to do raw materials inspection, on-site inspection and after finishing inspection to ensure 100% good quality of your carbide products.

3.Advanced CNC Equipment

We own a series of high-precision grind machines, including flat grinding machines, OD and ID machines, Centerless grinding machines and customized grinders. Also we have CNC machines, EDM, Wire-cutting machines and drilling machines etc. With our skilled workers, we can control very high precision of each carbide part.

4.Packaging and Shipping

Special-designed packing boxes and tubes will be used properly for the standard and customized carbide products to ensure the safety of the goods during the transportation process.A wide range of shipping ways can be available for your shipments, for example we can ship goods by Sea, by air and by Express companies like DHL/FedEx/UPS/TNT etc.