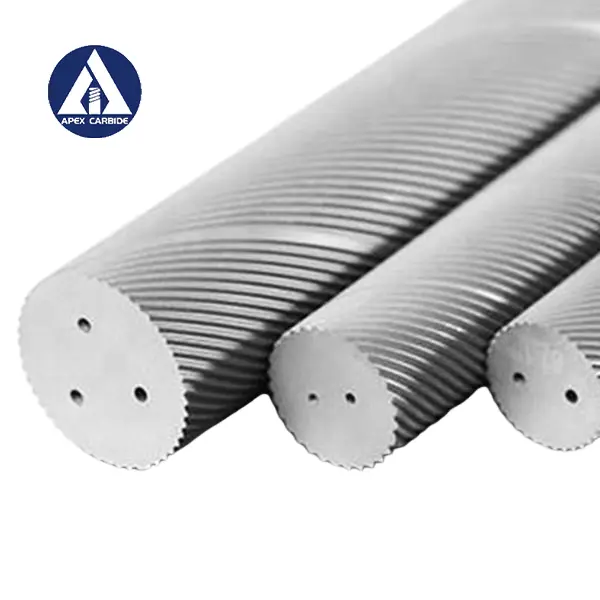

Tungsten Carbide-Tipped Saw Blades: Top Quality Options for Any Project

If you require high-quality Tungsten Carbide-Tipped Saw Blades that excel in cutting performance, our blades are crafted for exceptional durability and precision. These blades are designed for a wide range of applications across wood, metal, and other challenging materials. With extensive industry experience, we guarantee that our blades will boost your productivity and minimize downtime. We prioritize quality by sourcing the finest materials to ensure a longer lifespan. Our diverse range meets various needs, offering both standard sizes and custom solutions. Understanding the requirements of B2B purchases, we emphasize efficient and reliable service. For enhanced effectiveness of your Cutting Tools, contact us to discuss how Jiangxi Apex Carbide Co., Ltd. can provide superior Tungsten Carbide-Tipped Saw Blades to support your business objectives.

Methods To Choose Tungsten Carbide-Tipped Saw Blades Factory Products

When selecting tungsten carbide-tipped saw blades, it's crucial to consider several factors to ensure you choose the right products that meet your operational needs. First and foremost, understand the specific applications you require the saw blades for. Different materials, be it wood, metal, or composites, demand different blade specifications. Jiangxi Apex Carbide Co., Ltd specializes in high-quality cemented carbide products, offering a wide range of carbide rods, plates, and blades that are engineered for durability and performance in various industries. Next, evaluate the manufacturing process and the factory’s experience. A reputable factory, like Jiangxi Apex Carbide Co., Ltd, with an annual output of 2000 tons of carbide blanks, signifies reliability and expertise in producing top-tier products. Look for factories that utilize advanced technology and strict quality control measures to ensure that their saw blades meet international standards. Reviewing customer testimonials and case studies can provide insights into the performance and longevity of their products. Lastly, consider the customization options available. A factory that understands the diverse needs of the global market will offer tailored solutions to meet specific requirements. Jiangxi Apex Carbide Co., Ltd is committed to providing customizable carbide solutions, ensuring that their clients receive the best-fit products for their applications. By focusing on these methods, you can make informed purchasing decisions and enhance your operational efficiency with high-quality carbide-tipped saw blades.

Methods To Choose Tungsten Carbide-Tipped Saw Blades Factory Products

| Blade Type | Diameter (mm) | Teeth Count | Application | Material Processed | Price Range (USD) |

|---|---|---|---|---|---|

| Crosscut Blade | 250 | 80 | Wood | Softwood, Hardwood | 30 - 50 |

| Rip Blade | 300 | 24 | Wood | Softwood, Hardwood | 35 - 60 |

| Multi-Purpose Blade | 250 | 60 | All-purpose | Wood, Plastic, Laminate | 25 - 45 |

| Masonry Blade | 230 | 10 | Masonry | Bricks, Concrete | 40 - 75 |

| Metal Cutting Blade | 305 | 40 | Metal | Aluminum, Steel | 50 - 90 |

How To find Tungsten Carbide-Tipped Saw Blades Products Factory

Z

Zoey L. Mitchell

The quality of the product truly reflects high standards. The service team provided unwavering support.

21 May 2025

N

Noah R. Adams

The quality is superb, and the after-sales service made sure I had everything I needed.

28 June 2025

L

Liam B. Davis

Very pleased with the product quality! The service staff were incredibly helpful and professional.

27 June 2025

L

Layla C. Reyes

Superb quality product! Remarkably efficient assistance from the support team.

16 June 2025

A

Ava K. Morgan

This product is phenomenal! The service was equally commendable and professional.

15 May 2025

E

Ella G. Morgan

A delightful experience all around! Quality product backed by dedicated service.

15 May 2025